|

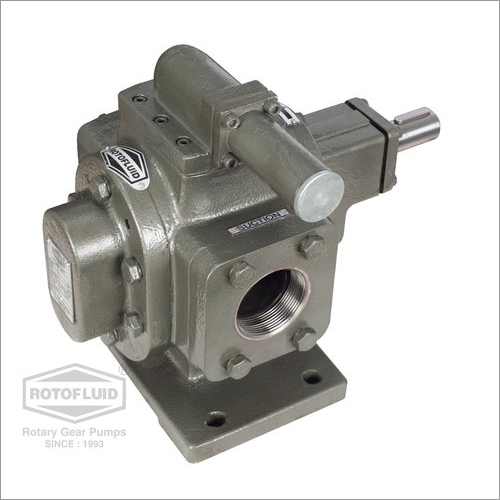

Crude Oil Gear Pump

Price 2500.00 INR/ Piece

Crude Oil Gear Pump Specification

- Working Temperature

- -10C to 120C

- Flow Rate

- 50 200 LPM

- Noise Level

- <70 dB

- Discharge Pressure

- 8 Bar

- Features

- Corrosion Resistant, Durable, Easy Maintenance

- Head Size

- Up to 50 meters

- Caliber

- 2 inches

- Mounting Type

- Base Mounted

- Control System

- Manual

- Frequency

- 50 Hz

- Speed

- 1440 RPM

- Voltage

- 220/380V

- Inlet/Outlet

- 2 BSP Threaded

- Max Suction

- 5 meters

- Theory

- Rotary Gear Pump

- Material

- Cast Iron

- Structure

- Gear Pump

- Power

- 1.5 kW 5.5 kW

- Standard

- IS Standards

- Pressure

- Up to 8 Bar

- Usage

- Crude Oil Transfer

- Application

- Industrial, Petrol Stations, Oil Refineries

- Suction Type

- Positive Displacement

- Seals Type

- Mechanical Seal or Gland Packing

- Priming

- Self-priming

- Pump Type

- Horizontal Rotary

- Capacity

- Up to 12 m/hr

- Viscosity Range

- Up to 1000 cSt

- End Connection

- Threaded/Flanged

- Direction of Rotation

- Clockwise

- Body Coating

- Anti-corrosive Paint

- Drive Type

- Coupled or V-belt Driven

Crude Oil Gear Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-5 Days

About Crude Oil Gear Pump

Engineered for Performance and Safety

The Crude Oil Gear Pump is built to meet the rigorous demands of crude oil transfer. Its horizontal rotary design ensures steady output, while the anti-corrosive paint and mechanical seals safeguard against harsh media, promoting operational safety and reliability over prolonged use.

Flexible Installation and Operation

This pump can be installed with either threaded or flanged end connections and is compatible with both coupled and v-belt drive systems. Its self-priming feature and positive displacement action allow consistent operation even under challenging suction conditions up to 5 meters.

Efficiency Meets Durability

Constructed from cast iron for resilience and coated for corrosion resistance, this gear pump boasts easy maintenance and low noise output under 70 dB. It is designed for high-capacity requirements, handling up to 12 m/hr at 50 Hz frequency, and is compliant with IS Standards.

FAQs of Crude Oil Gear Pump:

Q: How does the Crude Oil Gear Pump ensure efficient fluid transfer?

A: The pump utilizes a rotary gear mechanism that provides positive displacement, ensuring consistent fluid flow even with viscous crude oil. Its self-priming capability and powerful motor (1.5 kW 5.5 kW) contribute to efficient suction and transfer across a wide viscosity and flow range.Q: What materials and coatings are used to enhance the pumps durability?

A: The pumps body is manufactured from high-grade cast iron and coated with an anti-corrosive paint, protecting it from the corrosive nature of crude oil and harsh industrial environments, thereby extending its operational life.Q: Where is this pump typically used?

A: This gear pump finds application in industrial settings, petrol stations, and oil refineries across India. It is ideal for transferring crude oil due to its high durability, pressure tolerance, and suitability for harsh operational conditions.Q: When should I use a mechanical seal versus gland packing?

A: Mechanical seals are preferred for minimizing leakage in applications requiring higher reliability and reduced maintenance, whereas gland packing may be chosen for less critical operations or where seal replacement can be readily managed.Q: What is the recommended process for installation and start-up?

A: Ensure the pump is securely base-mounted, connect via threaded or flanged ends, and align the drive system (either coupled or v-belt). Verify the voltage compatibility (220/380V), prime the pump as per the manual, and gradually bring it up to its operating speed of 1440 RPM.Q: How does the control and maintenance of this pump work?

A: The pump features manual controls for straightforward operation. Its structure is designed for easy maintenance, with accessible sealing options (mechanical seal or gland packing) and cleaning features to maintain consistent performance.Q: What are the key benefits of using this gear pump for crude oil applications?

A: Operators benefit from a robust, corrosion-resistant design, flexible installation, and quiet operation (<70 dB). The pump meets IS Standards for safety and durability, offers high flow rates, and handles heavy-duty industrial oil transfer with minimal downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Pumps Category

Fuel Injection Gear Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Seals Type : Mechanical Seal

Priming : Self Priming

Flow Rate : 25100 LPH (Liters Per Hour)

Cast Iron Gear Pumps

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Seals Type : Mechanical seal / Gland packing

Priming : Self Priming

Flow Rate : Up to 500 LPM (Liters Per Minute)

Monoblock Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Seals Type : Mechanical Seal

Priming : Self Priming

Flow Rate : 20 LPM (Liters Per Minute)

Herringbone Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Seals Type : Mechanical Seal / Gland Packing

Priming : Self Priming

Flow Rate : 50 to 2000 LPH (Varies by Model)

|

FLUID TECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry