|

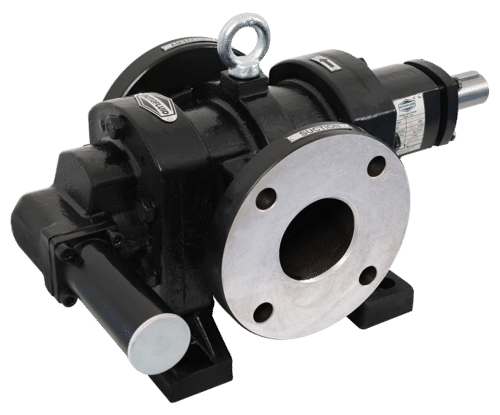

Stainless Steel Gear Pump

Stainless Steel Gear Pump Specification

- Control System

- Manual/Automatic

- Working Temperature

- Up to 200C

- Inlet/Outlet

- 1 x 1 (25mm x 25mm)

- Features

- Corrosion Resistant, Leak Proof, Easy Maintenance

- Caliber

- 25 mm

- Noise Level

- Low Noise

- Max Suction

- 5 Meter

- Voltage

- 220-415 V

- Frequency

- 50/60 Hz

- Discharge Pressure

- Up to 5 kg/cm

- Flow Rate

- 50 to 800 LPH

- Speed

- 1440-2880 RPM

- Head Size

- Up to 50 m

- Theory

- Rotary Pump

- Mounting Type

- Base Mounted

- Material

- Stainless Steel

- Structure

- Gear Pump

- Power

- 0.5 HP to 3 HP

- Standard

- ISI Certified

- Fuel Type

- Electric

- Pressure

- Up to 5 kg/cm

- Usage

- Industrial, Oil Transfer, Food Processing

- Application

- Chemical, Food, Pharma, Cosmetic Industries

- Suction Type

- Positive Suction

- Seals Type

- Mechanical Seal / Gland Packing

- Priming

- Self Priming

- Pump Type

- External Gear Pump

- Capacity

- Up to 48 m/day

- Shaft Material

- SS 304 / SS 316

- Connection Type

- Flanged/BSP Threaded

- Viscosity Handling

- Up to 1,00,000 CST

- Direction of Rotation

- Clockwise/Anti-clockwise

- Surface Finish

- Polished

- Body Material

- Stainless Steel SS 304 / SS 316

- Bearings

- Heavy Duty Ball Bearings

Stainless Steel Gear Pump Trade Information

- Minimum Order Quantity

- 01 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-5 Days

- Main Domestic Market

- All India

About Stainless Steel Gear Pump

Fluid Tech Systems offer ROTOFLUID brand gear pump Model FTSS (SS Rotary Gear Pump) which is self priming, foot mounting type positive displacement rotary gear pump. Model FTSS having all Stainless Steel (SS-316) in three piece construction with investment cast.Due to three piece construction, it can be easily cleanable and maintainable that is why it is highly used in all kind of food industries. These pumps have SS-316 Gear and shaft that are nitrated to give long life and trouble free performance. The shaft is supported on self lubricating type Ptfe coated Bushes and the sealing is done with Ptfe based GFO pack sealant which gives zero leakage. The right angle mounting brackets facilitates foot mounting of the pump on base plate with Electric Motor of appropriate ratings. These pumps have sturdy design and construction for long trouble free service.

The suction and delivery connection are available in 1/4 to 2 size. These pumps can be operated up to pressure of 10 kg/cm with 8.33 LPM to 300 LPM flow capacity and has suction lift of 1m to 5m at rated speed of 1440 RPM. These pumps are designed up to maximum Viscosity to 1,00,000 SSU and maximum temperature up to 200c.

Product details

|

Model |

FTSS |

|

Maximum Pressure |

100-150 bar |

|

Brand |

Rotofluid |

|

Discharge |

150-200 LPH |

|

Motor Horsepower |

3 HP |

|

Motor Speed |

2000 RPM |

|

Material |

SS |

Precision-Engineered Construction

Crafted with stainless steel SS 304 or SS 316 for both body and shaft, this gear pump is built to endure corrosive and high-temperature environments. Its polished surface finish and leak-proof design ensure clean, efficient transfer, particularly for sensitive chemical and food industry processes. Heavy-duty ball bearings further enhance operational longevity and reliability.

Versatile Applications and Performance

Capable of handling viscosities up to 1,00,000 CST, the pump is versatile for a range of sectors, including industrial oil transfer, chemical, food, pharmaceutical, and cosmetic processing. With a flow capacity ranging from 50 to 800 LPH and the ability to operate up to 48 m/day, it supports both high and low volume operations with consistent, precise flow.

Flexible Operation and Safety

Supported by manual or automatic control systems, this gear pump adapts easily to diverse application requirements. It meets ISI certification standards and can be integrated on base mounts for stability. Built-in features like easy maintenance, low noise, and self-priming enhance both user experience and operational safety.

FAQs of Stainless Steel Gear Pump:

Q: How does the Stainless Steel Gear Pump handle fluids with high viscosity?

A: This gear pump is designed to efficiently transfer fluids with viscosities up to 1,00,000 CST. Its positive suction capability and robust mechanical sealing ensure smooth, leak-proof operation even with thick or viscous liquids commonly found in industrial, food, and chemical applications.Q: What is the recommended process for maintaining the pump to ensure longevity?

A: Regularly inspect seals (mechanical or gland packing), ensure fluid paths are debris-free, and monitor bearings for wear. Since its constructed from corrosion-resistant stainless steel, routine cleaning with suitable agents helps maintain both hygiene and performance, particularly in food and pharmaceutical uses.Q: When should I use the manual versus the automatic control system?

A: Manual control is beneficial for applications requiring operator oversight or precise adjustment, such as batch processing. Automatic control suits continuous operations or integrated production lines, improving efficiency by minimizing human intervention and optimizing system responses.Q: Where is this pump most effectively used?

A: It is best utilized in environments demanding handling of corrosive, viscous, or high-temperature fluids. Common sectors include chemical manufacturing, food and beverage processing, pharmaceutical production, cosmetic preparation, and industrial oil transfer, where reliability and hygiene are critical.Q: What are the main benefits of choosing a gear pump with polished stainless steel construction?

A: Polished stainless steel minimizes contamination, improves cleaning efficiency, and increases corrosion resistance. This is especially valuable in industries where product purity, sanitary standards, and long equipment life are essential, such as food, pharma, and high-value chemical processes.Q: How does the self-priming feature benefit daily operations?

A: The self-priming capability enables the pump to evacuate air and begin fluid transfer without manual intervention. This reduces downtime, simplifies startup procedures, and ensures reliable performanceideal for busy industrial settings where operational efficiency matters.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Pumps Category

Fuel Injection Internal Gear Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Material : Cast Iron / Stainless Steel

Power : Other, 0.75 kW

Discharge Pressure : 26 bar

Petroleum Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Cast Iron/Steel

Power : Other, 0.75 kW to 18.5 kW

Discharge Pressure : Up to 10 Bar

Trochoidal Gear Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Material : Cast Iron / SS304 / SS316

Power : Other, 0.5 HP to 5 HP

Discharge Pressure : 6 to 8 Bar

Rotary Color Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Material : Cast Iron / Stainless Steel

Power : Other, 0.5 HP to 2 HP

Discharge Pressure : Up to 6 bar

|

FLUID TECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry