|

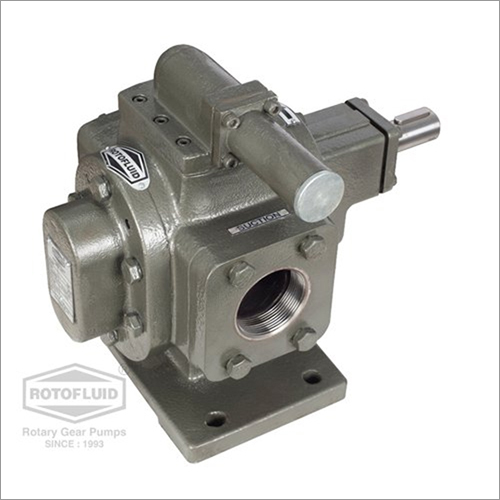

Diesel Twin Gear Pump

Diesel Twin Gear Pump Specification

- Working Temperature

- -10C to 80C

- Voltage

- 220V/380V

- Theory

- Rotary Pump

- Caliber

- 25 mm

- Max Suction

- 5 meters

- Inlet/Outlet

- 1 inch BSP

- Features

- Compact design, High efficiency, Long service life

- Head Size

- 20-30 meters

- Frequency

- 50 Hz

- Flow Rate

- 40-100 LPM

- Speed

- 1440 RPM

- Control System

- Manual

- Noise Level

- Below 75 dB

- Discharge Pressure

- Up to 6 Bar

- Mounting Type

- Base Mounted

- Material

- Cast Iron / Stainless Steel

- Structure

- Twin Gear

- Power

- 1 HP - 3 HP

- Standard

- ISO 9001:2015

- Fuel Type

- Diesel

- Pressure

- Up to 6 Bar

- Usage

- Diesel/Lubricant oil transfer

- Application

- Fuel Transfer, Industrial, Automotive

- Suction Type

- Positive Displacement

- Seals Type

- Mechanical Seal

- Priming

- Self Priming

- Pump Type

- Twin Gear Pump

- Capacity

- 40-100 LPM

- Weight

- Approx. 20-35 Kg

- Coupling Type

- Flexible Coupling

- Lubrication

- Splash Lubrication

- Rotation Direction

- Clockwise/Counterclockwise

- Shaft Material

- Alloy Steel

- Compliance

- CE Certified

- Viscosity Range

- 10-10000 cSt

- Drive Type

- Electric Motor Driven

- Temperature Range

- -10°C to 80°C

- Surface Finish

- Painted/Coated

Diesel Twin Gear Pump Trade Information

- Minimum Order Quantity

- 01 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-5 Days

- Main Domestic Market

- All India

About Diesel Twin Gear Pump

These pumps are having flange at the end of suction and delivery which are available in 1/2" to 6" size. These pumps can be operated up to pressure of 10 kg/cm² with 8.30 LPM to 2083.00 LPM flow capacity. These pumps are suitable for liquid up to viscosity of 1, 00,000 SSU and maximum temperature up to 200ºc.

Pump Selection

Model FTRN/FTRB : The self lubricated needle roller bearing type Model FTRN used for clean viscous liquid having sufficient lubricating property such as clean lube oil, Gear oil, Animal oil, Fish oil, Hydraulic oil, Honey, Vegetable oil, SAE lubricating oil for continues duty, However for Intermittent duty Bush Bearing type pump Model FTRB used.

Model FTRX : This Model independent lubricated needle roller bearing type pump is suitable for handling of Crude oil, Dirty lube oil, HSD, Kerosene, LDO, Paints, Varnish, Wood Pulp, Liquid which have poor lubricant value.

Model FTRBJ : This Model should be selected for liquid which tends to solidify at room temperature such as Bitumen, Furnace oil, Asphalt, Tar, Starch, Molasses, Naptha, RFO, Silicate, Wax, Soap solution. Because This model have jacketing construction facilitate the heating the pump by steam or thermic fluid.

Product details

| Voltage | 220V |

| Brand | Rotofluid |

| Model | FTNX |

| Frequency | 50Hz |

Versatile and Reliable Fuel Transfer

This Diesel Twin Gear Pump is engineered for efficient transfer of diesel and lubricant oils in demanding environments. Its self-priming capability and positive displacement design ensure consistent flow, even with viscous fluids. Flexible coupling mitigates vibration and extends equipment longevity, while the robust alloy steel shaft and high-quality mechanical seal deliver reliable and leak-free operation.

Industrial Grade and Easy Installation

Manufactured to international standards (CE, ISO 9001:2015), this pump is suitable for use in harsh industrial, automotive, or fuel handling settings. Its compact, base-mounted structure allows hassle-free installation and integration into new or existing systems. Painted or coated surfaces guarantee durability, while its manual control system ensures straightforward, user-centric operation.

FAQs of Diesel Twin Gear Pump:

Q: How does the twin gear mechanism improve pump performance?

A: The twin gear configuration provides precise and steady flow, ensuring efficient transfer of diesel and lubricating oils even at varying viscosities. The rotary action enables smooth operation, minimizes pulsation, and supports consistent performance across various industrial applications.Q: What are the primary benefits of using splash lubrication in this pump?

A: Splash lubrication ensures vital internal components receive adequate oiling without the need for complex lubrication systems, enhancing the pumps reliability and reducing maintenance requirements for prolonged service life.Q: Where can this diesel twin gear pump be installed?

A: This pump is ideal for installation in fuel transfer stations, industrial factories, automotive service facilities, and other environments requiring safe and efficient diesel or lubricant oil movement. Its compact design and base mounting facilitate integration into various setups.Q: What is the recommended process for installing and commissioning the pump?

A: Begin by securely base-mounting the pump, ensuring alignment with your piping. Connect the flexible coupling to the electric motor, wire to the appropriate voltage (220V/380V), and verify all seals and fixtures are tight. Check that the self-priming system is functional before initiating operation.Q: When should the mechanical seal be inspected or replaced?

A: The mechanical seal should be checked during routine maintenance intervals or if any leakage is observed. Regular inspection ensures reliable, leak-free operation and maximizes the pumps lifespan.Q: What makes this pump suitable for diesel and high-viscosity oil transfer?

A: Its positive displacement, rotary design effectively handles fluids with viscosities ranging from 10 to 10,000 cSt. The powerful motor, robust gears, and the self-priming feature enable it to manage viscous oils and diesel with ease.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Pumps Category

Viscous Liquid Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Seals Type : Mechanical Seal / Gland Packing

Power : Other, 0.5 HP to 10 HP

Theory : Other, Rotary Gear Pump

Material : Cast Iron / Stainless Steel

Double Helical Gear Pump

Minimum Order Quantity : 01 Piece

Seals Type : Mechanical Seal / Gland Packing

Power : Other, 0.5 HP to 50 HP

Theory : Other, Positive Displacement

Material : Cast Iron / Cast Steel / Stainless Steel

PD Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Seals Type : Mechanical seal

Power : Other, 0.5 HP

Theory : Other, Rotary gear pump

Material : Cast iron with hardened steel gears

Herringbone Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Seals Type : Mechanical Seal / Gland Packing

Power : Other, 0.37 kW to 18.5 kW

Theory : Other, Positive Displacement

Material : Cast Iron / Stainless Steel / Alloy Steel

|

FLUID TECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry