|

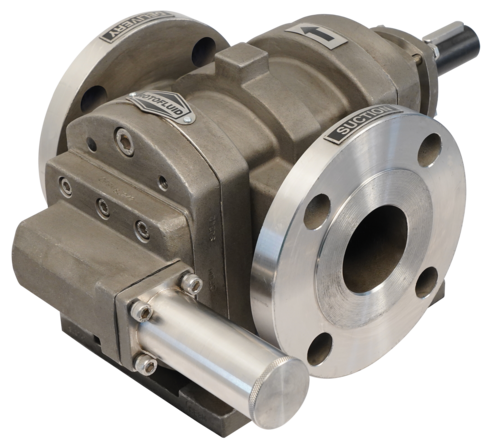

SS 316 Gear Pump

SS 316 Gear Pump Specification

- Noise Level

- Low

- Working Temperature

- Up to 180C

- Inlet/Outlet

- 1 x 1 (25mm x 25mm)

- Voltage

- 220V / 415V

- Theory

- Rotary Gear Pump

- Speed

- 1440 RPM

- Features

- Corrosion Resistant, Leak Proof, High Efficiency

- Frequency

- 50 Hz

- Caliber

- 25 mm

- Control System

- Manual

- Discharge Pressure

- Up to 3 kg/cm

- Head Size

- Up to 20 Meter

- Mounting Type

- Foot Mounted

- Flow Rate

- 20 to 450 LPH

- Max Suction

- Up to 5 Meter

- Material

- Stainless Steel 316

- Structure

- Single Stage

- Power

- 0.37 to 2.2 kW

- Standard

- ISO 5199

- Pressure

- Up to 3 kg/cm

- Usage

- Chemical Transfer, Food Processing, Pharmaceutical

- Application

- Acid, Alkali, Solvent, Oil, Syrup Transfer

- Suction Type

- Positive Suction

- Seals Type

- Mechanical Seal / Gland Packing

- Priming

- Self-Priming

- Pump Type

- External Gear

- Capacity

- 20 to 450 LPH

- Coupling

- Flexible Shaft Coupling

- Viscosity Handling

- Up to 50,000 cst

- Rotation

- Clockwise / Anti-clockwise

- Impeller Type

- Helical Gear

- Maximum Liquid Temperature

- 180°C

- Motor Phase

- Single/Three Phase

- Connection Type

- Flanged / Screwed

- Leakage Arrangement

- Double Mechanical Seal Available

- Mounting Orientation

- Horizontal

- Ambient Temperature

- Up to 45°C

- Body Finish

- Polished

- Weight

- Approx 15 Kg

- Maintenance

- Easy to Maintain

SS 316 Gear Pump Trade Information

- Minimum Order Quantity

- 01 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-5 Days

About SS 316 Gear Pump

Fluid Tech Systems offers ROTOFLUID brand gear pump Model FTMS(SS Rotary Twin Gear Pump, Foam Fire Fighting Gear Pump) which is heavy duty foot mounting type positive displacement rotary twin gear pump. Model FTMS having all stainless steel (SS-316) in four piece construction with investment cast. Due to four piece construction it can be easily cleanable and maintainable. These pumps having a double helical refined SS-316 gear shaft that are nitrated to give longer life. Due to Double halical gear it prevent axial and side thrust which help to increase life & performance of pump. The teflon coated dry running DU bush bearing, supported on bronze wearing plate, placed inside the pump casing, alternatively bronze wearing plate cum bushes can also be provided for thicker viscous liquid application. The stuffing box is fitted with GFO pack sealant with provision to fit mechanical shaft seal. These pumps provide with add-on type pressure relief valve. The jacketing construction should be selected to facilitate the heating of the pump by steam or thermic fluid etc.

These pumps having flange at the end of suction and delivery which are available in 1/2" to 6" size. These pumps can be operated up to pressure of 10 kg/cm2 with 13 LPM to 1335 LPM flow capacity. These pumps are suitable for maximum temperature up to 200oC and maximum viscosity up to 1,00,000 SSU

Product details :

| Design Type | external gear pump |

| Brand | ROTOFLUID |

| Motor Speed | 1440 RPM |

| Power Source | Pneumatic |

| Max Flow Rate | 2100 LPM |

| Model Number/Name | FTSS / FTMS |

Versatile Viscosity Handling

This gear pump can process fluids with viscosity levels up to 50,000 cst, making it suitable for diverse industrial applications including transferring heavy oils, syrups, and viscous chemicals. Its external helical gear impeller design ensures smooth operation and high efficiency, even with demanding liquids. Self-priming capabilities also allow efficient operation from dry starts.

Durable Construction and Finish

Crafted from SS 316 stainless steel and featuring a polished finish, the pump is highly resistant to corrosion and physical wear. The double mechanical seal arrangement and leak-proof structure provide reliable containment of aggressive and sensitive fluids, extending service life and minimizing maintenance requirements for critical processes.

Flexible Installation & Operation

The SS 316 Gear Pump can be mounted horizontally with foot mounting, and supports both clockwise and anti-clockwise rotation. It accommodates single or three phase motors and operates at standard voltages of 220V or 415V, ensuring compatibility across various facilities. Connections are available in flanged or screwed types, with manual control for ease of use.

FAQs of SS 316 Gear Pump:

Q: How does the SS 316 Gear Pump handle high-viscosity fluids?

A: The pump is specifically engineered to process fluids with viscosities up to 50,000 cst, utilizing a helical gear impeller and positive suction. This ensures reliable transfer of viscous liquids such as oils, syrups, and chemical solutions without compromising flow rate or efficiency.Q: What maintenance is required for the SS 316 Gear Pump?

A: Designed for easy maintenance, the pump features a polished SS 316 body and leak-proof seals. Regular inspection of seals, bearings, and shafts is recommended. The simple construction and mechanical seal arrangement facilitate straightforward cleaning and part replacement, minimizing downtime.Q: When is it suitable to use single-phase versus three-phase motor operation?

A: Single-phase motors are ideal for installations with standard household or low-power supply, while three-phase operation is preferred in industrial settings requiring higher efficiency and consistent performance. Both options are supported to match various user needs.Q: Where is the SS 316 Gear Pump typically installed?

A: This pump is commonly installed in chemical transfer stations, food processing plants, pharmaceutical factories, and industrial environments across India. It is suitable for horizontal, foot-mounted positioning, and can be connected via flanged or screwed fittings for versatile integration.Q: What is the process for transferring chemicals using this gear pump?

A: Fluid is drawn into the pump via positive suction, transported through the helical gear mechanism, and discharged with a flow rate between 20 and 450 LPH. The self-priming feature ensures quick startup, while double mechanical seals prevent leaks during chemical transfer.Q: What are the main benefits of choosing SS 316 construction for the gear pump?

A: SS 316 provides excellent corrosion resistance, durability in harsh environments, and sanitary properties for handling food-grade or pharmaceutical products. Its polished finish also resists scaling and facilitates easier cleaning and maintenance over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Pumps Category

Burner Firing Injection Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Pressure : Other, 525 bar

Noise Level : <70 dB(A)

Voltage : 220V / 380V

Inlet/Outlet : G1/2 or G3/4 Threaded

Monoblock Rotary Gear Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Pressure : Other, 6 bar (max)

Noise Level : Low

Voltage : 220240 V

Inlet/Outlet : 25 mm x 25 mm

Barrel Oil Gear Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Pressure : Other, 2.5 bar

Noise Level : Below 70 dB

Voltage : 220V / 380V

Inlet/Outlet : 1 inch / 1 inch

Crusher Oil Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Pressure : Other, 23 Bar

Noise Level : Low

Voltage : 220240 V

Inlet/Outlet : 1 x 1

|

FLUID TECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry