|

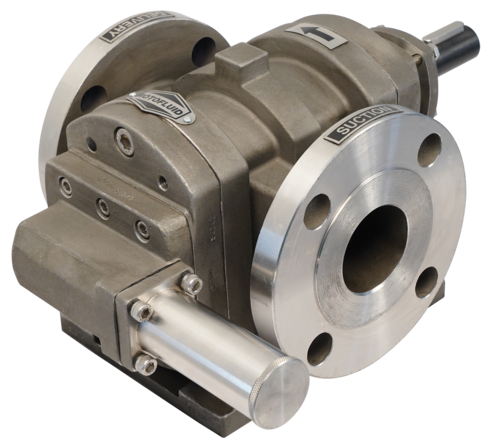

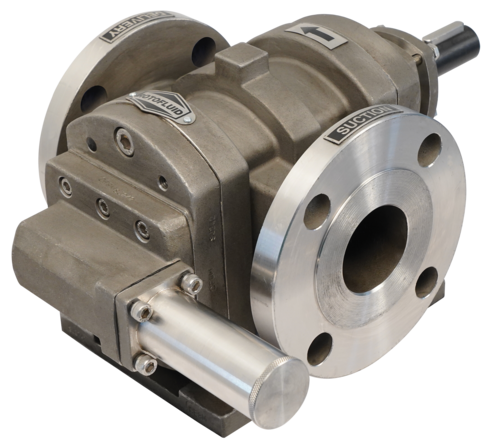

Chemical Gear Pumps

Price 2500.00 INR/ Piece

Chemical Gear Pumps Specification

- Flow Rate

- Up to 500 LPH

- Speed

- 1440 RPM / 2880 RPM

- Head Size

- Up to 50 meters

- Frequency

- 50 Hz / 60 Hz

- Caliber

- 1/4 to 2

- Discharge Pressure

- Up to 10 bar

- Inlet/Outlet

- Threaded / Flanged

- Mounting Type

- Base Mounted / Foot Mounted

- Noise Level

- Low Noise Operation

- Max Suction

- Up to 5 meters

- Voltage

- 230V/415V AC

- Control System

- Manual / Automatic

- Theory

- Positive Displacement Gear Principle

- Features

- Corrosion Resistant, High Efficiency, Leak Proof

- Working Temperature

- -10C to 180C

- Material

- Cast Iron, Stainless Steel, Bronze

- Structure

- Single Stage, Rotary Gear

- Power

- 0.25 HP to 5 HP

- Standard

- ISI / Custom

- Fuel Type

- Electric

- Pressure

- Up to 10 kg/cm

- Usage

- Chemical Transfer, Oil, Viscous Liquids

- Application

- Chemical Industry, Pharmaceutical, Food Processing

- Suction Type

- Positive Suction

- Seals Type

- Mechanical Seal / Gland Packing

- Priming

- Self Priming

- Pump Type

- Chemical Gear Pump

- Capacity

- 0.5 m/hr to 30 m/hr

- Body Finish

- Powder Coated / Painted

- Bearing Type

- Anti-Friction Ball Bearings

- Direction of Rotation

- Bidirectional

- Coupling Type

- Flexible

- Rotor Type

- Helical / Spur Gear

- Availability

- Ready Stock

- Service

- Continuous Duty

- Viscosity Handling Range

- Up to 1,00,000 cst

- Port Size

- As per requirement

Chemical Gear Pumps Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-5 Days

About Chemical Gear Pumps

Fluid Tech Systems offers ROTOFLUID brand gear pump Model FTMS (SS Rotary Twin Gear Pump, Foam Fire Fighting Gear Pump) which is heavy duty foot mounting type positive displacement rotary twin gear pump. Model FTMS having all stainless steel (SS-316) in four piece construction with investment cast. Due to four piece construction it can be easily cleanable and maintainable. These pumps having a double helical refined SS-316 gear shaft that are nitrated to give longer life. Due to Double halical gear it prevent axial and side thrust which help to increase life & performance of pump. The PTFE coated dry running DU bush bearing, supported on bronze wearing plate, placed inside the pump casing, alternatively bronze wearing plate cum bushes can also be provided for thicker viscous liquid application. The stuffing box is fitted with GFO pack sealant with provision to fit mechanical shaft seal. These pumps provide with add-on type pressure relief valve. The jacketing construction should be selected to facilitate the heating of the pump by steam or thermic fluid etc.

These pumps having flange at the end of suction and delivery which are available in 1/2" to 6" size. These pumps can be operated up to pressure of 10 kg/cm2 with 13 LPM to 1335 LPM flow capacity. These pumps are suitable for maximum temperature up to 200oC and maximum viscosity up to 1,00,000 SSU

Product details :

| Model | FTMS |

| Material | SS |

| Brand | Rotofluid |

| Motor Horsepower | 3 HP |

| Motor Speed | 2000 RPM |

| Discharge | 150-200 LPH |

| Maximum Pressure | 100-150 bar |

Versatile and Efficient Performance

These chemical gear pumps deliver consistent results regardless of liquid viscosity, handling up to 100,000 cst. Their robust construction and flexible mounting options ensure high efficiency and minimal noise. Suitable for both manual and automatic control systems, they meet diverse application needs, making them reliable for continuous-duty service.

Customizable For Diverse Applications

The pumps are designed with customizable port sizes, rotor types, and discharge options to suit your process requirements. Whether you need threaded or flanged connections, flexible coupling, or specific materials like Cast Iron, Stainless Steel, or Bronze, these pumps can be tailored for chemical, pharmaceutical, or food processing industries.

Built For Longevity and Safety

Powder coated or painted body finish, anti-friction ball bearings, and mechanical seals or gland packing ensure the pumps resist corrosion and operate leak-proof. With standard ISI certification and ready stock availability across India, these pumps guarantee reliability, safety, and quick deployment in critical chemical transfer processes.

FAQs of Chemical Gear Pumps:

Q: How do chemical gear pumps manage high-viscosity fluids up to 100,000 cst?

A: The pumps utilize a positive displacement gear mechanismeither helical or spur gear rotorsthat enables them to efficiently transfer extremely viscous liquids by generating constant flow regardless of fluid thickness.Q: What materials are available for the pump construction and which applications are they suitable for?

A: Pump bodies are manufactured in Cast Iron, Stainless Steel, and Bronze to cater to differing chemical compatibilities and process needs in chemical, pharmaceutical, and food processing industries.Q: When should I use mechanical seals versus gland packing for these pumps?

A: Mechanical seals offer superior leak protection and are preferable for hazardous or volatile chemicals, while gland packing is suitable for less demanding and more cost-sensitive operations.Q: Where can these chemical gear pumps be installed and how is mounting configured?

A: They are designed for base or foot mounting on industrial sites, allowing easy integration into pipelines or process lines for efficient chemical, oil, or viscous liquid transfer.Q: What is the process for selecting the correct port size and coupling type for my system?

A: Port sizes and coupling types are determined according to your specific flow rate requirements and piping setup. Customization is available to ensure seamless connections and optimal operation.Q: How does continuous duty service benefit my operations?

A: Continuous duty ensures the pumps can operate without interruption, increasing reliability in demanding chemical transfer processes, minimizing downtime, and supporting high-throughput applications.Q: What advantages do these pumps provide over other pump types for chemical transfer?

A: They are self-priming, support bidirectional operation, have high corrosion resistance, low noise levels, and precision leak-proof construction, ensuring safe and efficient chemical handling even in challenging environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Pumps Category

Foam Pressurizing Gear Pump

Minimum Order Quantity : 1 Piece

Noise Level : <75 dB

Max Suction : 6 m

Priming : Self Priming

Mounting Type : Base Mounted

Bottle Filling Machine Gear Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Noise Level : Low noise (<65 dB)

Max Suction : 23 meters

Priming : Selfpriming

Mounting Type : Table Top/Portable

Monoblock Rotary Gear Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Noise Level : Low

Max Suction : 5.5 meters

Priming : Selfpriming

Mounting Type : Base plate mounting

Rotary Gear Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Noise Level : Low Noise (<75 dB)

Max Suction : 5 Meter

Priming : Self Priming

Mounting Type : Foot / Base Mounted

|

FLUID TECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry