Most Popular Products

|

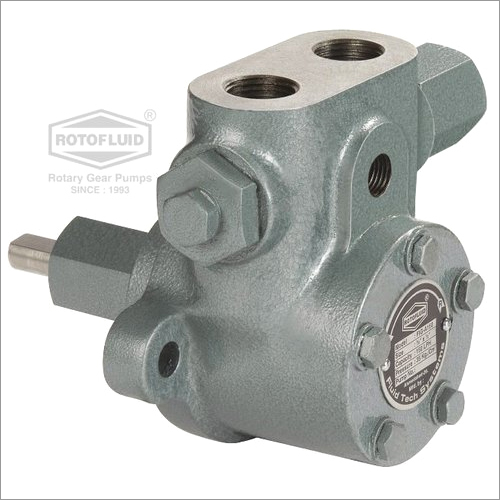

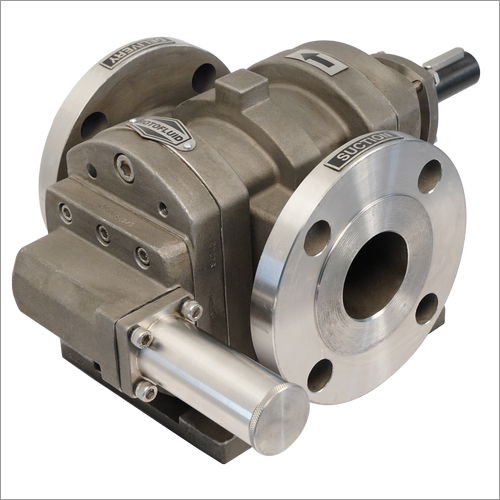

Corrosive Chemical Gear Pump

Price 2500.00 INR/ Piece

MOQ : 1 Piece

Corrosive Chemical Gear Pump Specification

- Flow Rate

- 0.5 m3/h to 30 m3/h

- Theory

- Rotary Gear Pump

- Control System

- Manual / Automatic

- Max Suction

- 5 Meter

- Frequency

- 50 Hz / 60 Hz

- Inlet/Outlet

- Threaded / Flanged

- Mounting Type

- Baseplate / Skid Mounted

- Noise Level

- <75 dB(A)

- Working Temperature

- -20C to 200C

- Voltage

- 220V / 380V

- Features

- Corrosion Resistant, Leak Proof, Compact Design, High Efficiency

- Head Size

- 10 m to 80 m

- Caliber

- 1/2 inch to 4 inch

- Discharge Pressure

- Up to 10 kg/cm

- Speed

- 960 to 2900 RPM

- Material

- PP / SS304 / SS316 / PVDF

- Structure

- Single Stage

- Power

- 0.5 HP to 20 HP

- Standard

- ISO 5199 / API 676

- Fuel Type

- Electric

- Pressure

- Max 10 Bar

- Usage

- Corrosive Chemical Transfer

- Application

- Acids, Alkalis, Solvents, Chemical Dosing, Chemical Processing, Effluent Handling, Textile, Dye, Water Treatment

- Suction Type

- Positive Suction

- Seals Type

- Mechanical Seal / Gland Packing

- Priming

- Self Priming

- Pump Type

- Corrosive Chemical Gear Pump

- Capacity

- Up to 30,000 LPH

- Viscosity Range

- upto 1,00,000 cSt

- Impeller Type

- External Gear

- Installation Position

- Horizontal

- Protection Class

- IP55 / IP65

- Surface Treatment

- Powder Coated / Polished

- Coupling

- Flexible Coupling

- Direction of Rotation

- Clockwise (viewed from coupling end)

Corrosive Chemical Gear Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-5 Days

About Corrosive Chemical Gear Pump

A corrosive chemical gear pump is a specialized pump designed to handle corrosive fluids in industrial applications. These pumps are constructed with materials that are resistant to corrosion, such as stainless steel, Hastelloy, or other corrosion-resistant alloys. They are specifically engineered to safely transfer corrosive chemicals, acids, and aggressive substances without experiencing degradation or damage.

FAQ:

Q: What are the main features of a corrosive chemical gear pump?

A: Corrosive chemical gear pumps are built with materials that have high resistance to corrosion, ensuring long-term durability and reliability when handling corrosive fluids. They often feature robust construction, tight clearances, and precise gear meshing to prevent leakage and provide efficient fluid transfer. These pumps may also have seals and gaskets made from chemically resistant materials to ensure proper containment of the corrosive fluid.

Q: What types of corrosive fluids can a corrosive chemical gear pump handle?

A: Corrosive chemical gear pumps are designed to handle a wide range of corrosive fluids, including acids (such as sulfuric acid, hydrochloric acid), alkalis (such as sodium hydroxide), solvents, and other aggressive chemicals. The selection of the pump materials should consider the specific corrosive properties of the fluid being pumped.

Q: Are corrosive chemical gear pumps suitable for high-pressure applications?

A: Corrosive chemical gear pumps can be designed to handle high-pressure applications, depending on the specific pump model and materials used. Pumps with robust construction, reinforced gear design, and suitable sealing mechanisms can effectively handle corrosive fluids at high pressures. It is important to select a pump that matches the pressure requirements of the application.

Q: What precautions should be taken when using a corrosive chemical gear pump?

A: When using a corrosive chemical gear pump, it is important to follow proper safety protocols. Personal protective equipment (PPE) should be worn, including gloves, goggles, and protective clothing. Adequate ventilation and containment measures should be in place to prevent exposure to fumes or leaks. Regular inspection and maintenance of the pump, including checking for signs of corrosion or wear, are also essential for safe and reliable operation.

Q: Can a corrosive chemical gear pump be used in hazardous environments?

A: Corrosive chemical gear pumps can be designed for use in hazardous environments, such as those classified as potentially explosive or containing flammable substances. Specialized pump models with appropriate certifications and safety features, such as explosion-proof motors and seals, can be selected for such applications. It is crucial to adhere to safety regulations and consult with experts to ensure compliance and safe operation.

Comprehensive Chemical Compatibility

Constructed from PP, SS304, SS316, or PVDF, this gear pump excels in transferring corrosive chemicals, including aggressive acids and alkalis. Its robust design ensures safe usage with solvents, dyes, and effluent treatments, making it a versatile solution for chemical processing industries and water treatment plants.

Engineered for High Performance and Safety

With self-priming functionality and positive suction, the pump delivers flow rates up to 30,000 LPH across a head range of 10 to 80 meters. It supports installation in hazardous environments, meeting IP55/IP65 protection standards, and operates smoothly within a noise level of less than 75 dB(A), ensuring safety and comfort for operators.

Flexible, Reliable Operation

Equipped with manual or automatic control systems, the gear pump fits a variety of setups, whether baseplate or skid-mounted. Its compact structure simplifies installation, while flexible coupling reduces alignment issues. The pump manages both threaded and flanged connections, accommodating different pipeline requirements in manufacturing or distribution facilities.

FAQs of Corrosive Chemical Gear Pump:

Q: How should the Corrosive Chemical Gear Pump be installed for optimal performance?

A: The pump should be installed horizontally on a stable baseplate or skid mount, ensuring alignment and proper coupling. Maintain adequate clearance for ventilation and service access, and install using the recommended threaded or flanged connections. For best results, follow the manufacturers guidelines regarding priming, suction piping, and electrical supply.Q: What types of chemicals and processes is this gear pump suitable for?

A: This gear pump is designed for transferring a wide range of corrosive chemicals, including acids, alkalis, solvents, and dyes. It is ideal for use in chemical dosing, chemical processing, effluent and water treatment, as well as textile industries where reliable handling of aggressive fluids is required.Q: When should I consider using mechanical seal versus gland packing for sealing?

A: Mechanical seals offer enhanced leak-proof protection for high-pressure or hazardous chemical applications, reducing maintenance and increasing safety. Gland packing is suitable for less demanding operations or where maintenance access is easier. The choice depends on your processs chemical compatibility, pressure, and environmental safety requirements.Q: Where is this pump typically utilized within industrial facilities?

A: The gear pump can be found in chemical plants, textile manufacturing, dye processing units, wastewater treatment facilities, and any industry requiring efficient corrosive chemical transfer. Its versatility allows for primary fluid transfer, process dosing, and effluent circulation within these settings.Q: What is the operational process of this Corrosive Chemical Gear Pump?

A: The pump operates on a rotary gear principle, utilizing external gears to move fluid from the inlet (suction side) to the outlet (discharge side) in a controlled, leak-proof manner. Its positive suction mechanism and self-priming design enable smooth startup and continuous operation, even with viscous or volatile fluids.Q: How does the pumps corrosion-resistant design benefit industrial users?

A: With construction materials like PP, SS304, SS316, and PVDF, the pump offers superior resistance to chemical attack, significantly extending service life even under harsh operating conditions. The powder-coated or polished surface further protects against corrosion, ensuring durability, minimal maintenance, and reduced downtime.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Gear Pumps Category

Double Helical Gear Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Max Suction : Up to 8 meters

Standard : IS, API, or customized

Flow Rate : 25 LPM to 1200 LPM

Loading Unloading Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Max Suction : 5 m

Standard : ISI / CE

Flow Rate : 50 to 500 LPM

Paint Gear Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Max Suction : 4 meters

Standard : ISO 9001:2015

Flow Rate : 6150 LPM

HSD Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Max Suction : 5 Meter

Standard : ISI / ISO 9001:2015

Flow Rate : 5 LPM to 500 LPM

|

FLUID TECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry