|

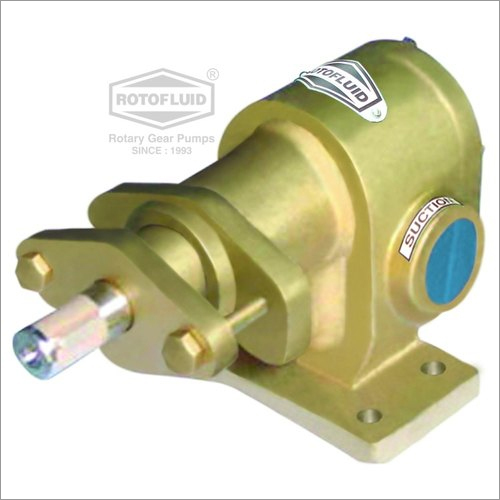

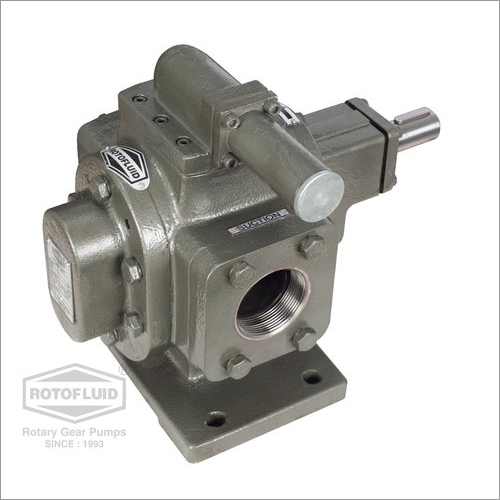

Gear Coupling Oil Pump

Price 2500.00 INR/ Piece

Gear Coupling Oil Pump Specification

- Theory

- Rotary Pump (Gear Mechanism)

- Max Suction

- 6 meters

- Inlet/Outlet

- 3/4 to 2 BSP (Customizable)

- Frequency

- 50/60 Hz

- Discharge Pressure

- Max 10 Bar

- Control System

- Manual/Automatic

- Caliber

- Standard/Custom as per requirement

- Speed

- Up to 1450 RPM

- Working Temperature

- -10C to +80C

- Flow Rate

- 30 LPM to 150 LPM

- Noise Level

- < 72 dB

- Voltage

- 220-415 V

- Head Size

- 10-40 meters

- Features

- Low Maintenance, Smooth Operation, High Efficiency

- Mounting Type

- Base Plate Mounted

- Material

- Cast Iron / Stainless Steel

- Structure

- Horizontal Mounting, Compact Design

- Power

- 0.5 HP - 5 HP

- Standard

- ISI / ISO 9001 Certified

- Fuel Type

- Oil, Light Viscous Liquids

- Pressure

- Up to 10 Bar

- Usage

- Oil Transfer, Lubrication, Hydraulic Oil, Diesel

- Application

- Industrial, Automotive, Machinery Lubrication

- Suction Type

- Positive Suction

- Seals Type

- Mechanical Seal / Lip Seal

- Priming

- Self Priming

- Pump Type

- External/Internal Gear Coupling Pump

- Capacity

- 10 LPM - 200 LPM

- Rotation Direction

- Clockwise/Counter-Clockwise

- Surface Finish

- Powder Coated / Painted

- Coupling Type

- Flexible/Solid Gear Coupling

- Weight

- Approx. 25-45 kg

- Protection Class

- IP55

- Service Life

- Long Service Life

- Shaft Material

- Alloy Steel

- Bearings

- Heavy Duty Ball/Roller Bearings

- Viscosity Range

- 20-1500 cSt

- Drive Type

- Electric Motor Driven

Gear Coupling Oil Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-5 Days

About Gear Coupling Oil Pump

Versatile Oil Transfer Solution

Engineered for a wide range of applications, the gear coupling oil pump is suitable for transferring lubricants, hydraulic oil, and diesel across industries. Its compatibility with both standard and custom calibers, plus positive suction up to 6 meters, ensures flexibility and dependability in industrial, automotive, and machinery lubrication requirements.

Robust Construction and Longevity

Built with alloy steel shafts, cast iron or stainless-steel bodies, and finished with powder coating or paint, this pump is designed to withstand demanding environments. Heavy-duty ball or roller bearings contribute to its long service life, while IP55 protection secures performance in challenging conditions.

Efficient, Smooth Operation

The pump utilizes a rotary gear mechanism for efficient, high-pressure fluid transfer. Its flexible drive system, electric motor compatibility, low noise level (<72 dB), and manual or automatic control system all contribute to smooth operation and minimal maintenance. Self-priming and high discharge pressure (up to 10 bar) enhance productivity in every application.

FAQs of Gear Coupling Oil Pump:

Q: How do I determine the correct rotation direction for my Gear Coupling Oil Pump?

A: The gear coupling oil pump can operate in both clockwise and counter-clockwise directions. Check your applications flow and piping requirements to select the suitable rotation direction, ensuring the best performance and correct installation.Q: What types of fluids can this pump handle, and what is the recommended viscosity range?

A: This pump is ideal for oil, hydraulic oil, diesel, and other light viscous liquids within a viscosity range of 20 to 1500 cSt. Always ensure the fluid complies with pump material compatibility and viscosity recommendations for optimal efficiency and longevity.Q: When should maintenance be performed on this oil pump?

A: Routine maintenance can be scheduled based on operating hours and application conditions, typically every 6 to 12 months. Regularly check for seal integrity, bearing condition, and clean any debris to maintain smooth operation and long service life.Q: Where is the Gear Coupling Oil Pump commonly used?

A: It is widely employed in industrial settings, automotive service stations, lubrication systems for machinery, and hydraulic oil transfer applications, providing reliable service across base plate mounted, compact horizontal installations.Q: What is the process for customizing inlet and outlet sizes?

A: Custom inlet and outlet sizes (from 3/4 to 2 BSP or beyond) can be specified during your order. Coordinate with the manufacturer or supplier to detail your requirements for tailored fit and seamless integration into existing systems.Q: How does the self-priming feature benefit the user?

A: The self-priming capability allows the pump to automatically draw fluids from the reservoir at start-up without manual priming, simplifying setup and improving operational efficiency, especially where frequent stops and starts occur.Q: What are the key advantages of choosing a flexible or solid gear coupling type?

A: Flexible gear couplings accommodate minor misalignments between the drive and pump, reducing stress on components and extending service life. Solid couplings ensure robust, precise torque transmission in stable, well-aligned systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Pumps Category

Double Helical Gear Pump

Minimum Order Quantity : 01 Piece

Pressure : Other, Up to 25 bar

Suction Type : Positive suction

Theory : Other, Positive Displacement

Power : Other, 0.5 HP to 50 HP

Textile Machine Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Pressure : Other, Up to 6 bar

Suction Type : Positive Displacement

Theory : Other, Rotary Gear Pump

Power : Other, 0.5 HP

Industrial Rotary Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Pressure : Other, Up to 10 Bar

Suction Type : Positive Suction

Theory : Other, Rotary Gear Pump

Power : Other, 0.5 HP to 50 HP

Herringbone Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Pressure : Other, Up to 10 Bar

Suction Type : Positive Suction

Theory : Other, Positive Displacement

Power : Other, 0.37 kW to 18.5 kW

|

FLUID TECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry