|

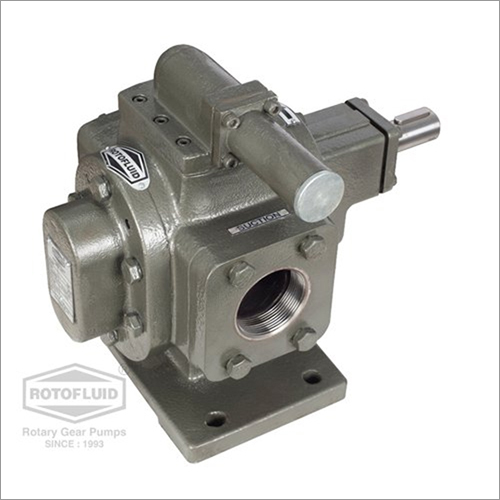

High Pressure Gear Pump

Price 2500.00 INR/ Piece

High Pressure Gear Pump Specification

- Mounting Type

- Foot / Flange Mounted

- Noise Level

- < 70 dB

- Features

- Leak-proof operation, High efficiency, Compact design, Easy maintenance

- Frequency

- 50 Hz / 60 Hz

- Caliber

- Standard / As per request

- Head Size

- Up to 100 meters

- Theory

- Rotary Gear Pump

- Voltage

- 415V / 380V / 220V / 110V (as per requirement)

- Discharge Pressure

- Up to 25 Bar

- Working Temperature

- -10C to +80C

- Max Suction

- Up to 5 meters

- Inlet/Outlet

- 1/2 inch to 4 inch BSP(F/NPT)

- Flow Rate

- Up to 500 LPM (liter per minute)

- Speed

- Up to 3500 RPM

- Control System

- Manual / Electric Panel Operated

- Material

- Cast Iron / Alloy Steel / Stainless Steel

- Structure

- Single / Double Stage

- Power

- 0.5 HP to 30 HP

- Standard

- IS / ISO certified

- Fuel Type

- Diesel / Oil / Fuel

- Pressure

- Up to 25 Bar

- Usage

- Industrial, Hydraulic Oil, Lubricants, Fuel Transfer

- Application

- Hydraulic Systems, Oil Transfer, Lubrication

- Suction Type

- Positive Displacement

- Seals Type

- Mechanical Seal / Gasket

- Priming

- Self-priming

- Pump Type

- High Pressure Gear Pump

- Capacity

- Up to 30 m/h

- Direction of Rotation

- Clockwise / Counter Clockwise

- Shaft Material

- EN-8 / EN-353 / Stainless Steel

- Bearings

- Anti-friction ball/roller bearing

- Viscosity Range

- Up to 1,00,000 SSU

- Port Size

- As per model selection

- Paint Finish

- Anti-corrosive coating

- Weight

- Varies with model (approx. 20-250 kg)

High Pressure Gear Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-5 Days

About High Pressure Gear Pump

Versatile Material and Customization

Choose from sturdy construction materials like Cast Iron, Alloy Steel, or Stainless Steel for optimal compatibility with various industrial liquids. The high-pressure gear pump can be customized according to application needs, with port sizes and mounting types adjusted per specific requirements. The robust anti-corrosive coating ensures lasting performance even under demanding conditions.

Wide Viscosity and Temperature Range

Our pumps operate efficiently with fluids up to 100,000 SSU and tolerate temperatures from -10C to +80C, making them suitable for a broad range of industrial and hydraulic systems, as well as fuel and oil transfer. The design ensures reliable priming and consistent operation even with viscous or temperature-sensitive liquids.

Easy Operation and Maintenance

Enjoy intuitive operation, thanks to manual or electric panel controls. With self-priming capability, anti-friction bearings, and simple access for maintenance, these pumps minimize downtime and operational complexities. Leak-proof seals and compact footprints enable safe and hassle-free installation in tight or challenging environments.

FAQs of High Pressure Gear Pump:

Q: How does the high pressure gear pump ensure leak-proof operation?

A: The pump is equipped with high-quality mechanical seals or gaskets, anti-friction ball or roller bearings, and an anti-corrosive coating. These features collectively minimize leakage, enhance durability, and support leak-proof performance even under high pressure and speed.Q: What are the typical industrial uses of this high pressure gear pump?

A: This gear pump is primarily used in hydraulic systems, oil transfer, lubrication tasks, fuel transfer (diesel, oil, or fuel), and a variety of industrial and process applications requiring robust, reliable fluid handling and pressure capability.Q: When should I select specific shaft or body materials like EN-8, EN-353, or stainless steel?

A: Material choice depends on the liquid being pumped and the environmental conditions. Use stainless steel for corrosive fluids, EN-8 or EN-353 for standard industrial oils, and alloy steel or cast iron for general industrial usage. Customization ensures compatibility and longevity.Q: Where should the pump be installed for optimal performance?

A: Install the pump near the fluid source, ensuring the suction line is as short and straight as possible. Choose foot or flange mounting as per your system setup, and follow standard IS/ISO guidelines for safety and efficiency.Q: What is the maintenance process for this gear pump?

A: Routine checks involve inspecting seals, bearings, and lubrication, as well as cleaning the inlet/outlet ports. The design facilitates easy maintenance, allowing for quick seal or bearing replacement without significant downtime.Q: How does the self-priming feature benefit my operation?

A: Self-priming capability allows the pump to remove air from the suction line and start pumping fluid without manual intervention. This feature enhances operational convenience, particularly in applications where frequent starts or stops occur.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Pumps Category

Viscous Liquid Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Theory : Other, Rotary Gear Pump

Structure : Other, Horizontal / Foot Mounted

Seals Type : Mechanical Seal / Gland Packing

Inlet/Outlet : 1 inch 4 inch

Reversible Rotary Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Theory : Other, Rotary Gear Pump

Structure : Other, Rotary Gear Type

Seals Type : Mechanical Seal / Gland Packing

Inlet/Outlet : 1 to 4 BSP / Flanged

Three Phase Helical Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Theory : Other, Helical Gear

Structure : Other, Single/Double Stage

Seals Type : Mechanical Seal

Inlet/Outlet : 1 x 1 BSP (customizable)

Filling Machine Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Theory : Other, Positive Displacement

Structure : Gear Pump

Seals Type : Mechanical Seal

Inlet/Outlet : 25mm / 25mm

|

FLUID TECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry