|

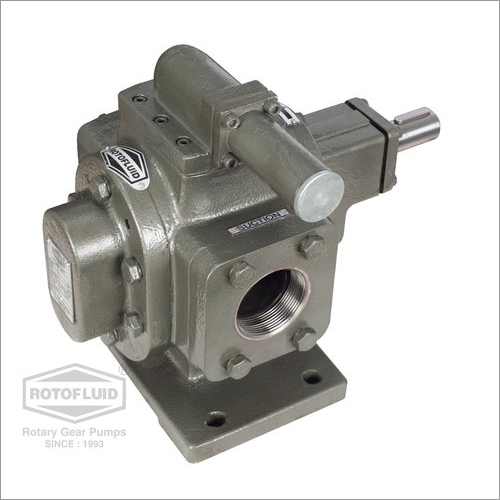

Herringbone Gear Pump

Price 2500.00 INR/ Piece

Herringbone Gear Pump Specification

- Control System

- Manual / Automatic (Depends on Installation)

- Features

- Low Noise, High Efficiency, Self Priming, Durable Construction

- Head Size

- Up to 10 Bar

- Inlet/Outlet

- Flanged / Threaded

- Theory

- Positive Displacement

- Discharge Pressure

- Up to 10 Bar

- Noise Level

- Low

- Working Temperature

- Up to 150C

- Max Suction

- Up to 8 Meter

- Voltage

- Not Applicable (Mechanical Drive)

- Mounting Type

- Base Mounted / Foot Mounted

- Flow Rate

- 50 to 2000 LPH (Varies by Model)

- Caliber

- Up to 150 mm

- Speed

- Up to 1450 RPM

- Material

- Cast Iron / Stainless Steel / Alloy Steel

- Structure

- Herringbone Gear Internal Mechanism

- Power

- 0.37 kW to 18.5 kW

- Standard

- ISI / ISO Standards

- Pressure

- Up to 10 Bar

- Usage

- Industrial / Oil Transfer / Chemical Processing

- Application

- Oil, Lube, Fuel, Viscous Liquids, Chemicals

- Suction Type

- Positive Suction

- Seals Type

- Mechanical Seal / Gland Packing

- Priming

- Self Priming

- Pump Type

- Herringbone Gear Pump

- Capacity

- 50 to 2000 LPH

- Direction of Rotation

- Clockwise or Counterclockwise

- Coupling Type

- Flexible or Rigid Coupling

- Viscosity Range

- Up to 1,00,000 cSt

- Surface Finish

- Corrosion Resistant Coating

- Number of Stages

- Single

- Bearing Type

- Anti-Friction Bearings

- Lubrication

- Self Lubricating Gears

- Shaft Material

- High Tensile Steel

Herringbone Gear Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-5 Days

About Herringbone Gear Pump

Durable and Versatile Design

Engineered with herringbone gear internal mechanisms and high tensile steel shafts, this pump promises long service life and optimal performance in diverse sectors. Its corrosion-resistant coating supports extended durability in challenging environments, while self-lubricating gears minimize maintenance.

Flexible Installation Options

The Herringbone Gear Pump allows both base and foot mounting, suited to varying industrial requirements. Available in different materialscast iron, stainless steel, or alloy steelit accommodates a wide range of fluids, ensuring compatibility with various process conditions.

Optimized for Industrial Flow Control

Supporting manual or automatic control systems, this pump is efficiently tailored for oil, lubricant, chemical, and fuel transfer. Its ability to handle high viscosities and provide steady flow rates highlights its suitability for critical industrial applications.

FAQs of Herringbone Gear Pump:

Q: How does the Herringbone Gear Pump ensure high efficiency when handling viscous liquids?

A: Thanks to its robust positive displacement theory and precision-engineered herringbone gears, the pump efficiently manages fluids with viscosities up to 1,00,000 cSt. The self-priming feature and self-lubricating gears further enhance operational efficiency and reduce energy losses during transfer.Q: What process should be followed to install the Herringbone Gear Pump in an industrial setting?

A: Installation entails securing the base or foot-mounted pump to a stable platform, connecting flanged or threaded inlet/outlet ports, and aligning the flexible or rigid coupling to the drive system. Seal type (mechanical or gland packing) should be chosen based on fluid characteristics and leakage requirements.Q: When should mechanical seal or gland packing be chosen as the seal type?

A: Mechanical seals are recommended for applications involving hazardous or high-pressure fluids, as they offer superior leak prevention. Gland packing is suitable for standard industrial fluids and lower pressure systems, providing a cost-effective sealing method with straightforward maintenance.Q: Where can the Herringbone Gear Pump be used most effectively?

A: This pump is highly effective in sectors such as oil refineries, chemical plants, lubrication systems, fuel transfer stations, and any setting requiring reliable handling of viscous or corrosive fluids. Its corrosion-resistant and robust construction ensures dependable service in demanding environments.Q: What are the primary benefits of using a herringbone gear mechanism in this pump?

A: The herringbone gear design provides smoother flow with reduced pulsation and noise. It also distributes forces evenly, reducing gear wear and extending service life, which makes the pump highly reliable and efficient for continuous industrial operations.Q: How is the flow rate controlled in the Herringbone Gear Pump?

A: Flow rate can be managed through manual or automatic control systems, depending on installation. Adjusting the drive speed or using appropriate control valves allows fine-tuning of the flow between 50 and 2000 LPH, catering to specific process requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Pumps Category

External Gear Pump

Minimum Order Quantity : 01 Piece

Flow Rate : 10 LPM to 500 LPM (varies by model)

Material : Cast Iron / Stainless Steel / Bronze

Standard : IS/ISO compliant

Mounting Type : Horizontal/Base Mounted

Diesel Rotary Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Flow Rate : 38 LPM

Material : Cast Iron

Standard : IS Standard

Mounting Type : Base Mounted

Oil Transfer Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Flow Rate : 30 L/min

Material : Cast Iron

Standard : ISI

Mounting Type : Foot mounted

Diesel Transfer Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Flow Rate : 40 LPM

Material : Cast Iron

Standard : IS 4897

Mounting Type : Base Mounted

|

FLUID TECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry