|

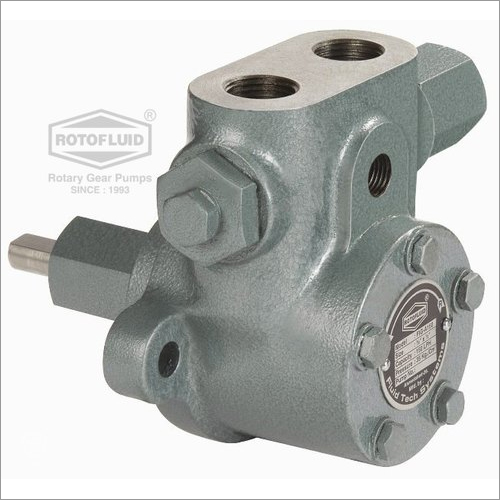

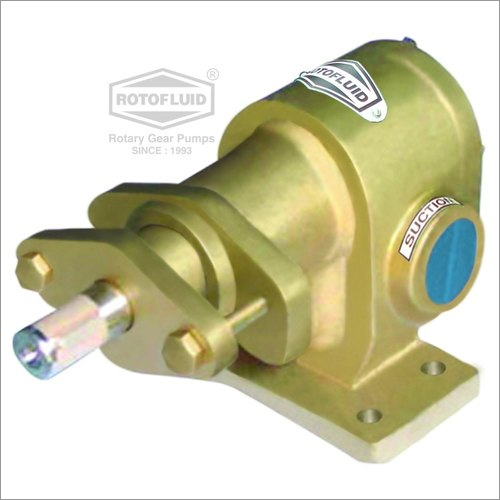

Gunmetal Gear Pump

Price 2500.00 INR/ Piece

Gunmetal Gear Pump Specification

- Caliber

- Standard as per model selection

- Noise Level

- Low noise operation

- Mounting Type

- Flange / Foot Mounted

- Max Suction

- Up to 7.5 meters

- Head Size

- Up to 90 meters

- Discharge Pressure

- Up to 10 kg/cm

- Flow Rate

- Up to 400 LPM

- Inlet/Outlet

- 1 to 3 BSP (optional flange end)

- Control System

- Manual / Electric starter

- Working Temperature

- -10C to 120C

- Theory

- Rotary gear mechanism

- Features

- Corrosion resistant, heavy duty construction, robust performance

- Frequency

- 50 Hz / 60 Hz

- Voltage

- 230 V AC / 415 V AC

- Speed

- Up to 1440 RPM

- Material

- Gunmetal / Bronze

- Structure

- Close-coupled / Base mounted

- Power

- 0.5 HP to 25 HP

- Standard

- ISO 9001:2015

- Fuel Type

- Compatible with oil, diesel, lubricants

- Pressure

- Max 10 kg/cm

- Usage

- Oil transfer, chemical processing, fuel handling

- Application

- Industrial / Commercial / Marine

- Suction Type

- Positive displacement

- Seals Type

- Mechanical seal / Gland packing

- Priming

- Self priming

- Pump Type

- Rotary Gear Pump

- Capacity

- Up to 24 m/hr

- Body Construction

- Cast gunmetal body

- Servicing

- Easy maintenance and servicing design

- Shaft Material

- Alloy steel / Stainless steel

- Impeller Type

- Precision-cut gear

- Direction of Rotation

- Clockwise (standard), Counter clockwise (optional)

- Cooling

- Air cooled

- Surface Finish

- Smooth machined bronze

- Max Solid Handling

- Not suitable for solids

- Viscosity Range

- Up to 1,00,000 SSU

- Port Size

- Available in multiple sizes

- Seal Material

- Viton / PTFE / Nitrile options

Gunmetal Gear Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-5 Days

About Gunmetal Gear Pump

Precision Engineering for Lasting Performance

Constructed with a cast gunmetal body and precision-cut gear impellers, the Gunmetal Gear Pump ensures efficient fluid transfer, corrosion resistance, and minimal noise. Its rugged design is ideal for demanding environments, ensuring both longevity and robust operation even under variable viscosity and pressure requirements.

Versatile Application Across Industries

This pump supports a wide range of uses including oil transfer, chemical processing, and fuel handling. With multiple port sizes, mounting options, and manual or electric start controls, it adapts to both industrial and commercial installations. The positive displacement mechanism and self-priming action simplify setup and operation.

FAQs of Gunmetal Gear Pump:

Q: How do I select the correct direction of rotation for the Gunmetal Gear Pump?

A: You can choose between standard clockwise or optional counterclockwise rotation based on your systems configuration. The selected direction should match the intended flow direction and mechanical setup for optimal performance.Q: What types of fluids are compatible with this gear pump?

A: This pump is designed to transfer oils, diesel, lubricants, and chemicals with viscosity up to 100,000 SSU. It is not suitable for fluids containing solids, as its mechanism is not designed for solid handling.Q: When should I perform maintenance or servicing on the pump?

A: Routine maintenance is recommended based on usage frequency. Typically, visual checks and seal inspections should be done every few months, with periodic servicing to ensure seals and gears remain in good condition.Q: Where can the Gunmetal Gear Pump be installed?

A: It is suitable for installation in industrial, commercial, or marine settings. The pump offers both flange and foot mounting options, allowing flexibility for different operational environments and space constraints.Q: What is the process for changing the seal materials?

A: Seal material replacementavailable in Viton, PTFE, or Nitrilecan be done during regular servicing. The pumps easy maintenance design enables quick access to the sealing components, reducing downtime.Q: How does self-priming benefit fluid transfer operations?

A: The self-priming feature allows the pump to evacuate air and commence fluid transfer without manual priming. This greatly simplifies startup and improves reliability in various applications.Q: What are the advantages of choosing a gunmetal gear pump for industrial use?

A: This pump offers superior corrosion resistance, heavy-duty operation, and low noise production. It meets ISO 9001:2015 standards, providing robust and dependable performance for critical fluid handling tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Pumps Category

LDO Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Theory : Rotary Pump

Usage : Other, LDO, Furnace Oil, Diesel, HSD, FO Transfer

Features : Rugged Design, Easy Maintenance, Leak Proof

Application : Other, Fuel Transfer, Industrial Liquid Handling

Cast Iron Gear Pumps

Minimum Order Quantity : 01 Piece

Theory : Other, Rotary Pump (External Gear type)

Usage : Other, Industrial oil transfer, Hydraulic oil, Fuel oils

Features : Self priming, sturdy construction, reliable operation, easy maintenance

Application : Other, Chemical, Pharmaceuticals, Petrochemical, Food, Paint, Oil, Lubricant transfer

Industrial Rotary Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Theory : Other, Rotary Gear Pump

Usage : Other, Industrial / Chemical / Oil Transfer

Features : High Efficiency, Corrosion Resistant, Low Maintenance

Application : Other, Refineries, Chemical Plants, Oil Mills, Pharmaceuticals, Food Processing

SS Foam Fire Fighting Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Theory : Other, Rotary Gear Pump

Usage : Other, Fire Fighting Foam Transfer

Features : Corrosion resistant, High efficiency, Durable construction

Application : Other, Fire Fighting Systems

|

FLUID TECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry