|

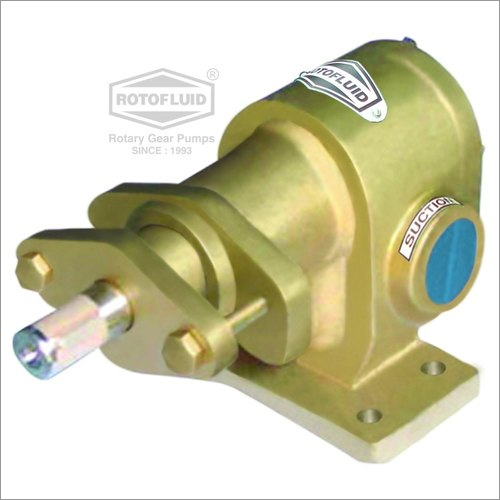

Loading Unloading Gear Pump

Price 2500.00 INR/ Piece

Loading Unloading Gear Pump Specification

- Control System

- Manual/Automatic

- Fuel Tank Capacity

- Depends on external tank

- Frequency

- 50 Hz

- Voltage

- 380V / 415V

- Features

- High Efficiency, Compact Design, Easy Maintenance

- Working Temperature

- -10C to 80C

- Mounting Type

- Foot Mounted

- Inlet/Outlet

- 2 inch / 2 inch

- Noise Level

- Low

- Speed

- 1440 RPM

- Head Size

- 15 m

- Caliber

- 2 inch

- Max Suction

- 5 m

- Theory

- Rotary Gear Pump

- Discharge Pressure

- Up to 10 Bar

- Flow Rate

- 50 to 500 LPM

- Material

- Cast Iron / Stainless Steel

- Structure

- Single Stage

- Power

- 1.5 kW to 7.5 kW

- Standard

- ISI / CE

- Fuel Type

- Diesel, Oil, Kerosene

- Pressure

- 6-10 Bar

- Usage

- Loading/Unloading of Fuel and Oil

- Application

- Industrial, Petrochemical, Chemical, Oil Transfer

- Suction Type

- Positive Displacement

- Seals Type

- Mechanical Seal

- Priming

- Self Priming

- Pump Type

- External Gear Pump

- Capacity

- 0.5 to 30 m/hr

- Bearings

- Ball Bearing

- Direction of Rotation

- Clockwise/Counterclockwise

- Surface Finish

- Painted/Polished

- Flange Connection

- ANSI/BS/DIN Standard

- Protection Class

- IP55

- Shaft Material

- EN8/SS316

- Service Life

- Above 25,000 Hours

- Flow Adjustment

- Bypass Valve

- Coupling Type

- Flexible Coupling

- Viscosity Range

- 10 to 10000 cSt

- Pump Weight

- Approx. 38-45 kg

Loading Unloading Gear Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-5 Days

About Loading Unloading Gear Pump

Versatile Viscosity Handling

This gear pump is capable of efficiently handling liquids with viscosities ranging from 10 to 10,000 cSt, making it ideal for loading and unloading a wide variety of oils and fuels, including diesel, kerosene, and heavy oils. Its positive displacement rotary mechanism ensures steady performance even with varying fluid types and conditions.

Robust Construction for Longevity

Engineered with high-quality materials such as EN8 or SS316 shaft and cast iron or stainless steel body, the pump ensures durability and resistance against wear and corrosion. Ball bearings and mechanical seals further enhance reliability, offering a service life of over 25,000 operational hours.

Flexible and Safe Operation

The unit is designed for various control needsmanual or automaticwhile featuring an IP55 protection class for safety. ANSI/BS/DIN flange compatibility and flexible coupling allow for easy installation and integration into existing systems. Its self-priming feature and low noise operation are suited for demanding work environments.

FAQs of Loading Unloading Gear Pump:

Q: How does the loading unloading gear pump handle different types of fuel and oil?

A: The pumps rotary gear design and positive displacement mechanism allow it to efficiently transfer fuels and oils with viscosities from 10 to 10,000 cSt. Its robust construction and self-priming capability ensure smooth handling of different liquids, including diesel, kerosene, and lubricating oils.Q: What maintenance process is required for optimal performance?

A: The pump requires periodic inspection of the ball bearings, mechanical seals, and bypass valve. Regularly check for any fluid leaks, ensure coupling alignment, and keep the surface clean. The design allows easy access for maintenance, resulting in minimal downtime and upkeep costs.Q: When should I use the bypass valve for flow adjustment?

A: The integrated bypass valve should be used for regulating the flow and pressure within the specified range of 50 to 500 LPM and up to 10 Bar discharge pressure. It is particularly useful during loading and unloading operations to match system requirements or prevent pump overload.Q: Where can this gear pump be installed?

A: The pump can be installed in any industrial, petrochemical, chemical, or oil transfer facility, thanks to foot-mounted design and flange compatibility with ANSI, BS, or DIN standards. Its suitable for both indoor and outdoor use, with protections against dust and moisture (IP55 rated).Q: What are the benefits of a self-priming, positive displacement gear pump?

A: Self-priming allows the pump to start smoothly without external priming, saving operational time. The positive displacement principle ensures constant flow, reliable suction up to 5 meters, and stable performance even with fluctuating pressure and viscosity.Q: How does the flexible coupling improve operation?

A: The flexible coupling minimizes transmission vibrations, compensates for minor misalignments, and protects both the motor and pump from undue stress. This leads to quieter operation, longer service life, and smoother start-up.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Pumps Category

Twin Gear Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Suction Type : Positive Suction

Power : Other, 0.5 HP to 60 HP

Pressure : Other, Up to 10 bar

Paint Gear Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Suction Type : Positive Displacement

Power : Other, 0.25 HP to 5 HP

Pressure : Other, Max 10 bar

Gear Coupling Oil Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Suction Type : Positive Suction

Power : Other, 0.5 HP 5 HP

Pressure : Other, Up to 10 Bar

Gunmetal Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Suction Type : Positive displacement

Power : Other, 0.5 HP to 25 HP

Pressure : Other, Max 10 kg/cm

|

FLUID TECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry