|

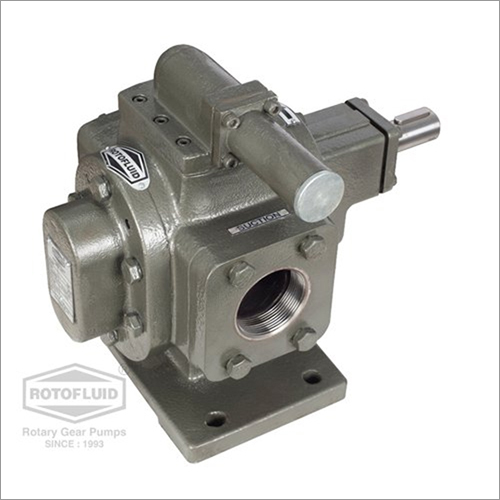

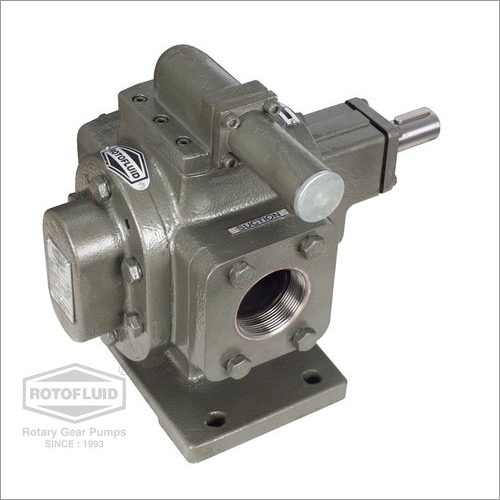

Viscous Fluid Transfer Gear Pump

Price 2500.00 INR/ Piece

Viscous Fluid Transfer Gear Pump Specification

- Max Suction

- 6 Metres

- Control System

- Manual / Automatic

- Noise Level

- Low

- Inlet/Outlet

- 1 / 1.5 / 2 / Custom

- Theory

- Rotary Gear Pump

- Features

- Corrosion Resistant, Easy Maintenance, High Viscosity Handling

- Mounting Type

- Base Mounted / Flange Mounted

- Caliber

- Customizable

- Voltage

- 220V / 380V

- Speed

- Up to 1440 RPM

- Head Size

- Up to 100 Metres

- Flow Rate

- Up to 300 LPM

- Frequency

- 50 Hz

- Working Temperature

- -10C to 120C

- Discharge Pressure

- Up to 10 Bar

- Material

- Cast Iron / Stainless Steel

- Structure

- Single Stage External Gear

- Power

- 0.5 HP to 20 HP

- Standard

- ISI / CE

- Fuel Type

- Electric

- Pressure

- Up to 10 Bar

- Usage

- Viscous Fluid Transfer

- Application

- Oil, Syrup, Paint, Resin, Chemicals, Lubricants

- Suction Type

- Positive Suction

- Seals Type

- Mechanical Seal / Gland Packing

- Priming

- Self-priming

- Pump Type

- Rotary Gear Type

- Capacity

- Up to 18 m/h

- Lubrication

- Self Lubricating

- Pump Body Finish

- Powder Coated / Painted

- Drive Type

- Electric Motor / Engine Driven

- Coupling Type

- Flexible / Rigid

- Protection Class

- IP55

- Viscosity Range

- Up to 500,000 cSt

- Connection Standard

- BSP / NPT / DIN

- Max Particle Size

- Up to 0.5 mm

- Operating Mode

- Continuous / Intermittent

- Impeller Material

- Alloy Steel / Cast Iron

- Rotation Direction

- Bi-directional

Viscous Fluid Transfer Gear Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-5 Days

About Viscous Fluid Transfer Gear Pump

Superior Handling of High-Viscosity Fluids

This rotary gear pump is purpose-built to manage viscous materials, with a capacity to transfer fluids up to 500,000 cSt. Its powerful self-lubricating design and positive suction ensure smooth performance, even with challenging substances like paint, syrup, and lubricants. The self-priming feature further enhances operational readiness, minimizing downtime.

Flexible and Durable Construction

Every component is built for versatility and longevity. The pump supports customizable inlet and outlet sizes, various mounting configurations, and is available with different coupling and seal types. Its alloy steel or cast iron impeller, powder-coated or painted finish, and resistance to corrosion make it suitable for diverse environments.

Ideal for Industrial Applications

Designed for the demands of industrial use, this gear pump is perfect for transferring oils, chemicals, and other dense fluids. With ISI/CE certification, IP55 protection, and operation in temperatures from -10C to 120C, it thrives in rigorous conditions. Its quiet operation, automated or manual controls, and high reliability ensure user confidence.

FAQs of Viscous Fluid Transfer Gear Pump:

Q: How does the Viscous Fluid Transfer Gear Pump handle thick or sticky fluids?

A: The pump utilizes a robust rotary gear mechanism capable of efficiently transferring fluids with viscosities up to 500,000 cSt. Its self-lubricating and positive suction features enable smooth, clog-free operation, even with dense materials such as oils, resins, and paint.Q: What are the primary benefits of using this gear pump in industrial settings?

A: This pump provides high reliability, low noise levels, and resistance to corrosion. Its flexible design allows for continuous or intermittent operation, customizable connections, rapid self-priming, and easy maintenance, making it highly suitable for demanding industrial applications.Q: When is it necessary to use a pump with bi-directional rotation capability?

A: Bi-directional rotation is beneficial when you need to reverse flow direction during processes like tank filling or emptying, or when a systems process requires flow alternation without physically repositioning the pump.Q: Where can this pump be installed for optimal performance?

A: It can be mountable on a base or flange, making it versatile for indoor factory floors, chemical processing plants, or areas requiring robust, reliable fluid transfer. The IP55 protection class ensures durability in environments exposed to dust and water spray.Q: What is the recommended process for maintaining the Viscous Fluid Transfer Gear Pump?

A: Routine maintenance is straightforward due to its easy-access design. Periodic checks of the seals, impeller, and lubrication system are recommended. Its self-lubrication feature minimizes the need for frequent servicing.Q: How does the pump accommodate different connection and sealing needs?

A: The inlet and outlet can be tailored to various standards such as BSP, NPT, or DIN, with diameter options of 1, 1.5, 2 inches, or custom. Customers can choose between mechanical seals or gland packing to suit their application and fluid type.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Pumps Category

Viscous Liquid Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Cast Iron / Stainless Steel

Priming : Self Priming

Head Size : Up to 100 meters

Pressure : Other, Max 10 kg/cm

HSD Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Cast Iron / Stainless Steel

Priming : Self Priming

Head Size : Up to 100 meter

Pressure : Other, Up to 10 bar

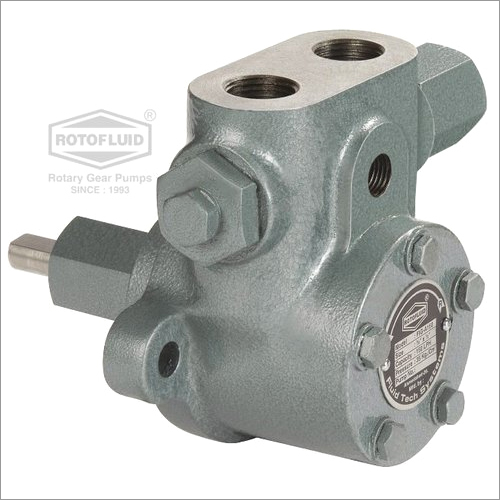

Fluid Coupling Rotary Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Cast Iron

Priming : SelfPriming

Head Size : 1080 meters

Pressure : Other, Up to 10 Bar

Twin Gear Pump

Minimum Order Quantity : 01 Piece

Material : Cast Iron, Stainless Steel

Priming : Self Priming

Head Size : Up to 100 meters

Pressure : Other, Up to 10 Bar

|

FLUID TECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry