|

Filling Machine Gear Pump

Price 2500.00 INR/ Piece

Filling Machine Gear Pump Specification

- Mounting Type

- Horizontal

- Frequency

- 50Hz/60Hz

- Flow Rate

- 12-20 L/min

- Theory

- Positive Displacement

- Control System

- Manual/Electronic

- Caliber

- 25mm

- Features

- Corrosion resistant, high precision, easy maintenance

- Inlet/Outlet

- 25mm / 25mm

- Discharge Pressure

- Max 1.2 MPa

- Speed

- 1450 rpm

- Max Suction

- 5 meters

- Head Size

- 8-25 meters

- Voltage

- 220V/380V

- Working Temperature

- -10C to 60C

- Noise Level

- <72 dB

- Material

- Stainless Steel

- Structure

- Gear Pump

- Power

- 0.55kW

- Standard

- ISO 9001

- Fuel Type

- Electric

- Pressure

- 1.2 MPa

- Usage

- Filling Machine

- Application

- Liquid Filling

- Suction Type

- Direct Suction

- Seals Type

- Mechanical Seal

- Priming

- Self-priming

- Pump Type

- Rotary Gear

- Capacity

- Up to 20L/min

- Weight

- 7 kg

- Protection Grade

- IP54

- Service Life

- More than 3000 hours

- Cable Length

- 1.5 m

- Maximum Viscosity Handled

- 2000 cps

- Direction of Rotation

- Reversible

Filling Machine Gear Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-5 Days

About Filling Machine Gear Pump

Robust & Versatile Construction

Made from premium stainless steel, this gear pump offers excellent corrosion resistance for long-lasting durability. The reversible rotation and direct suction design provide flexibility in liquid transfer, while compatibility with both 220V and 380V ensures suitability for different setups. Its 1.5m cable and horizontal mounting type simplify installation.

Efficient Performance & Safety

Operating at a speed of 1450 rpm with a low noise level under 72 dB, this pump delivers a flow rate of up to 20L/min. The IP54 protection grade safeguards the pump against dust and splashing water, while the mechanical seal ensures secure operation. Engineered for precise and continuous use, it boasts a service life exceeding 3000 hours.

FAQs of Filling Machine Gear Pump:

Q: How does the self-priming feature benefit the filling process?

A: The self-priming capability allows the pump to quickly draw liquids up from the inlet without manual intervention, streamlining the filling process and reducing downtime. This feature is particularly advantageous when dealing with intermittent or batch operations.Q: What types of liquids can this gear pump handle?

A: It is designed to handle a wide range of liquids with viscosities up to 2000 cps, making it suitable for fluids such as oils, syrups, chemicals, and other industrial liquids requiring precise filling applications.Q: Where is the ideal installation site for this filling machine gear pump?

A: The pump is best suited for use in industrial environments like filling lines, production facilities, or bottling plants. Its horizontal mounting type and IP54-protected structure make it adaptable to both indoor and sheltered outdoor settings.Q: What processes or machinery can integrate with this gear pump?

A: This gear pump can be integrated into automated and semi-automated filling machines, production conveyors, and liquid transfer systems that require accurate and consistent dosing of liquids.Q: When should maintenance be performed on this pump?

A: Regular maintenance, such as seal inspections and cleaning, is recommended at intervals according to your operation hours. Given its service life of over 3000 hours, periodic checks can ensure continued optimal performance and longevity.Q: How is the direction of rotation controlled, and why does it matter?

A: The direction of rotation is reversible and can be set manually or electronically. This feature offers flexibility in liquid transfer operations, allowing both forward and backward pumping as needed for cleaning, priming, or operational adjustments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Pumps Category

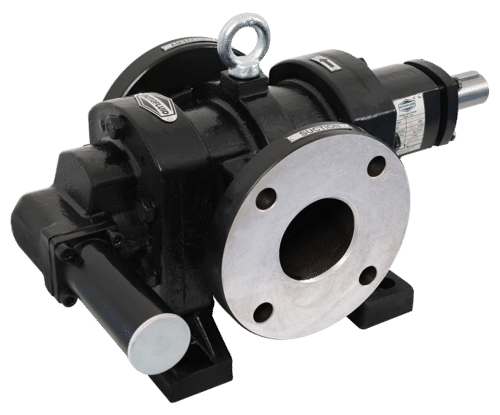

Petroleum Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Head Size : Up to 80 meters

Pump Type : Other, Gear Pump

Voltage : 220380 V

Cast Iron Gear Pumps

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Head Size : Up to 90 meters

Pump Type : Other, External Gear Pump

Voltage : 220V / 415V

Trochoidal Gear Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Head Size : 10 m to 40 m

Pump Type : Other, Trochoidal Gear Pump

Voltage : 220240V AC / 380415V AC (as per model)

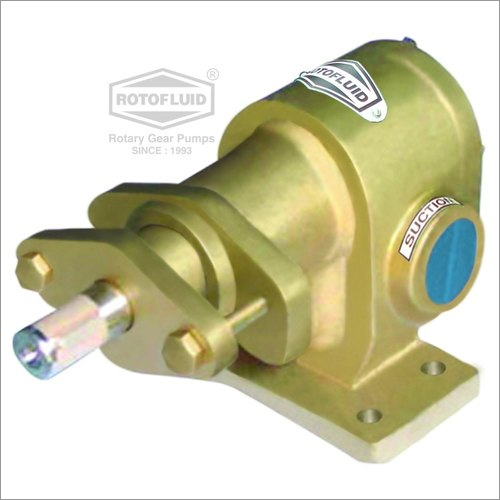

Gunmetal Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Head Size : Up to 90 meters

Pump Type : Other, Rotary Gear Pump

Voltage : 230 V AC / 415 V AC

|

FLUID TECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry