|

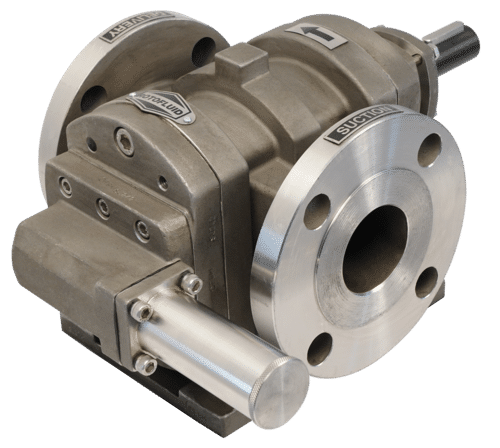

HSD Gear Pump

Price 2500.00 INR/ Piece

HSD Gear Pump Specification

- Features

- High Efficiency, Leak Proof, Robust Construction, Long Life

- Max Suction

- 5 Meter

- Noise Level

- Low

- Head Size

- Up to 100 meter

- Frequency

- 50 Hz / 60 Hz

- Working Temperature

- -5C to +180C

- Flow Rate

- 5 LPM to 500 LPM

- Control System

- Manual / Automatic

- Discharge Pressure

- Customizable as per requirement

- Mounting Type

- Foot Mounted

- Caliber

- Adjustable as per model

- Theory

- Rotary Gear Pump

- Inlet/Outlet

- 3/8 to 3 BSP (Female Threaded)

- Speed

- Up to 1440 RPM

- Voltage

- 220-415V

- Material

- Cast Iron / Stainless Steel

- Structure

- Horizontal Mount

- Power

- 0.25 HP to 20 HP

- Standard

- ISI / ISO 9001:2015

- Fuel Type

- Diesel, Oil, Chemical

- Pressure

- Up to 10 bar

- Usage

- Industrial, Fuel Transfer, Chemical Processing

- Application

- Lubricant Oils, Edible Oil, Viscous Liquids, Bitumen, Syrup

- Suction Type

- Positive Suction

- Seals Type

- Mechanical Seal / Gland Packing

- Priming

- Self Priming

- Pump Type

- HSD Gear Pump

- Capacity

- 5 LPM to 500 LPM

- Suitable Fluids

- Hydraulic Oil, LDO, HSD, Glycerin, Acids, Alkali, Solvents

- Connector Type

- Threaded / Flanged

- Viscosity Range

- Up to 1,00,000 cst

- Temperature Resistance

- High

- Body Finish

- Anti Corrosive Paint

- Design

- Compact

- Impeller Type

- External Spur Gears

- Rotation

- Clockwise (Standard) / Counter Clockwise (Optional)

HSD Gear Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-5 Days

About HSD Gear Pump

Versatile Applications and High Efficiency

The HSD Gear Pump expertly manages diverse fluids, including chemicals, oils, and viscous liquids such as bitumen and syrup. Its adaptable design accommodates various industries, from fuel transfer and lubricant distribution to food processing. High efficiency, low noise emission, and leak-proof operation ensure a reliable performance even under challenging conditions.

Robust Construction and Flexible Configuration

Manufactured with durable materials like cast iron or stainless steel and an anti-corrosive finish, the pump is well-suited for harsh industrial settings. The modular design offers customizable inlet/outlet sizes, discharge pressures, and control systems, allowing end-users and distributors to specify features according to operational requirements.

User-Friendly Installation and Maintenance

Featuring a foot-mounted structure and available in horizontal mount, the HSD Gear Pump allows straightforward installation. Threaded and flanged connectors provide easy integration with existing systems. Its self-priming and positive suction project reduced downtime, while robust seals ensure minimal maintenance and an extended service life.

FAQs of HSD Gear Pump:

Q: How is the HSD Gear Pump installed and integrated into existing systems?

A: The HSD Gear Pump can be easily installed using its foot-mounted, horizontal structure with either threaded or flanged connectors, enabling seamless integration into a variety of industrial pipelines and processes.Q: What types of fluids can this gear pump handle efficiently?

A: This pump is designed to handle fluids with viscosities up to 100,000 cst, including hydraulic oil, LDO, HSD, edible oils, glycerin, acids, alkali, solvents, bitumen, and syrup, making it suitable for a wide array of industrial and chemical applications.Q: When should mechanical seals be chosen over gland packing for this pump?

A: Mechanical seals are preferred for high-pressure, high-temperature, or hazardous fluid applications, while gland packing is suitable for less demanding operational conditions or when lower maintenance costs are desired.Q: Where is this pump most effectively used?

A: The HSD Gear Pump is extensively utilized in industrial settings such as fuel transfer stations, chemical processing plants, lubricant oil circulation, and factories dealing with viscous or corrosive liquids.Q: What is the process for adjusting flow rate and discharge pressure?

A: Flow rate and discharge pressure can be adjusted by selecting the appropriate model with the required caliber and head specifications. Discharge pressure is also customizable according to end-user requirements.Q: How does the self-priming feature benefit pump operation?

A: Self-priming ensures that the pump starts and operates efficiently without manual intervention, even when the suction line is not completely filled with liquid, reducing downtime and improving safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Pumps Category

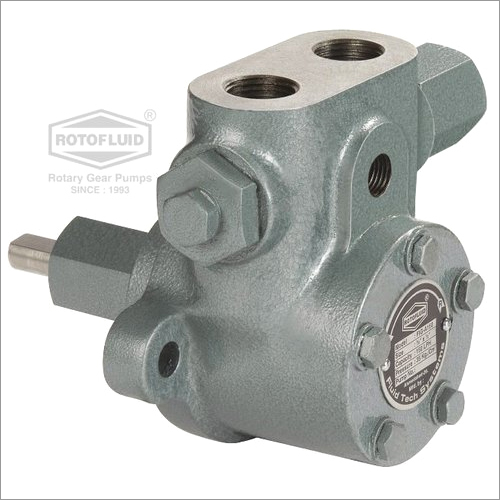

Loading Unloading Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Suction Type : Positive Displacement

Pressure : Other, 610 Bar

Power : Other, 1.5 kW to 7.5 kW

SS Twin Gear Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Suction Type : Positive Suction

Pressure : Other, Up to 10 Bar

Power : Other, 0.5 HP to 5 HP

Rotary Twin Gear Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Suction Type : Positive Suction

Pressure : Other, Upto 10 Bar

Power : Other, 0.5 HP to 100 HP

Diesel Transfer Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Suction Type : Positive Displacement

Pressure : Other, 3 bar

Power : Other, 0.75 kW

|

FLUID TECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry