Most Popular Products

|

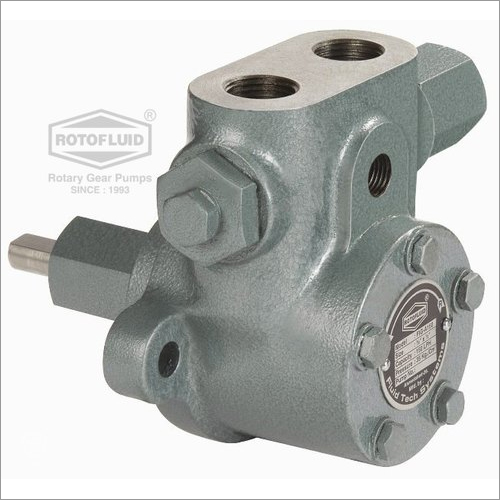

Paint Transfer Gear Pump

Price 2500.00 INR/ Piece

MOQ : 1 Piece

Paint Transfer Gear Pump Specification

- Mounting Type

- Base Mounted

- Frequency

- 50/60 Hz

- Features

- High Efficiency, Leak Proof, Corrosion Resistant

- Max Suction

- 5 meters

- Noise Level

- Low (<70 dB)

- Theory

- Rotary Pump

- Control System

- Manual/Auto

- Flow Rate

- 10-50 LPM

- Inlet/Outlet

- 1 inch / 1 inch

- Voltage

- 220V/380V

- Speed

- 1440 RPM

- Discharge Pressure

- Up to 1.5 MPA

- Working Temperature

- -10C to 80C

- Caliber

- 25 mm

- Head Size

- 10-20 meters

- Material

- Cast Iron/Stainless Steel

- Structure

- Gear Pump

- Power

- 0.5 HP to 3 HP

- Standard

- ISO 9001:2015

- Fuel Type

- Electric

- Pressure

- 0.5 - 1.5 Mpa

- Usage

- Paint Transfer

- Application

- Industrial Paint Transfer

- Suction Type

- Positive Suction

- Seals Type

- Mechanical Seal

- Priming

- Self Priming

- Pump Type

- Rotary Gear Pump

- Capacity

- 0.5 - 5 m3/hr

- Service Life

- Over 10,000 hours

- Max Solid Content

- Up to 2% by volume

- Direction of Rotation

- Clockwise/Counter-clockwise

- Viscosity Range

- Up to 5000 cSt

- Drive Type

- Electric Motor Driven

Paint Transfer Gear Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-5 Days

About Paint Transfer Gear Pump

A paint transfer gear pump is a specialized pump designed for the transfer and circulation of paint and coatings in various applications, including automotive painting, industrial painting, furniture manufacturing, and other paint-related industries. These pumps are specifically engineered to handle the unique characteristics of paint, such as its viscosity, solids content, and potential presence of pigments or additives. They play a crucial role in ensuring accurate and efficient paint transfer, delivering a consistent and high-quality finish.

FAQ:

Q: What are the key features of a paint transfer gear pump?

A: Paint transfer gear pumps are designed with features that make them suitable for handling paint and coatings. These pumps typically have a robust construction with materials that are compatible with the paint being transferred, such as stainless steel or non-reactive coatings. They are designed to handle the relatively high viscosity of paint and accommodate the potential presence of pigments or additives. The gear design provides precise flow control, ensuring accurate paint transfer and minimizing pulsation.

Q: What are the advantages of using a paint transfer gear pump?

A: Using a paint transfer gear pump offers several advantages in paint-related applications. These pumps provide accurate and consistent paint transfer, ensuring a uniform finish and reducing material waste. They can handle a wide range of paint viscosities, including high-viscosity paints, without compromising performance. Paint transfer gear pumps also offer precise flow control, allowing for precise application and minimizing overspray. Their robust construction ensures reliability and longevity, even when handling abrasive or corrosive paint formulations.

Q: Can a paint transfer gear pump handle different types of paint and coatings?

A: Yes, paint transfer gear pumps are designed to handle various types of paint and coatings commonly used in industrial applications. This includes solvent-based paints, water-based paints, epoxy coatings, polyurethane coatings, and other paint formulations. It is crucial to ensure that the pump materials and design are compatible with the specific paint being transferred to ensure optimal performance and longevity.

Q: Are paint transfer gear pumps suitable for high-pressure applications?

A: Paint transfer gear pumps are typically not designed for high-pressure applications but are more suited for low to moderate pressure requirements commonly encountered in paint transfer and circulation systems. They are designed to provide consistent and accurate flow rates rather than high-pressure capabilities. It is important to select a pump that matches the pressure requirements of the specific paint application.

Q: How do I ensure proper maintenance and longevity of a paint transfer gear pump?

A: Proper maintenance and care are important for the longevity and performance of a paint transfer gear pump. Regularly inspecting the pump for wear or damage, cleaning and flushing the pump after each use, and following recommended maintenance procedures are crucial steps. This may include replacing worn parts, checking for leaks or blockages, and ensuring proper lubrication of gears and bearings. Following the manufacturer's guidelines and consulting with experts can help ensure proper maintenance practices.

Reliable Paint Transfer for Industrial Needs

With a robust construction and precision engineering, the Paint Transfer Gear Pump delivers consistent and efficient paint handling performance. Its self-priming ability, positive suction, and high discharge pressure make it ideal for demanding environments, ensuring uninterrupted operation and maintaining paint quality throughout the process.

Versatility and Adaptability

Supporting a wide viscosity range and dual-directional rotation, this pump seamlessly integrates with different systems and installation requirements. The mechanical seal and corrosion-resistant materials minimize maintenance, while low noise operation and multiple control options (manual or auto) enhance workplace comfort and automation potential.

Long Service Life and Compliance

Designed for over 10,000 hours of operation and manufactured to ISO 9001:2015 standards, the pump promises reliability and efficiency. Its leak-proof design and resistance to harsh chemicals support cleaner and safer industrial environments, reducing downtime and increasing productivity.

FAQs of Paint Transfer Gear Pump:

Q: How does the Paint Transfer Gear Pump operate for different paint viscosities?

A: The pump is engineered to handle paints with viscosities up to 5000 cSt, thanks to its rotary gear design and electric motor drive. This allows efficient transfer of thin to moderately thick paints without risking clogging or performance loss.Q: What is the process for installing and setting up the Paint Transfer Gear Pump?

A: Installation involves base mounting the pump, connecting the 1-inch inlet and outlet ports, and providing an appropriate 220V or 380V electrical supply. The pump can be rotated in either direction, making setup flexible for existing pipelines, and supports both manual and automatic control systems.Q: When should the pumps maintenance be performed for optimal service life?

A: Routine checks are recommended every 6 to 12 months or as indicated in the manufacturers maintenance schedule. Thanks to high-quality mechanical seals and corrosion-resistant materials, the pump is designed for over 10,000 hours of service under standard operating conditions.Q: Where can this gear pump be used most effectively?

A: This pump is ideal in industrial facilities for transferring paint during manufacturing, processing, or packaging. Its suited for both small and large operations and can be sourced from distributors, exporters, manufacturers, suppliers, and wholesalers throughout India.Q: What are the primary benefits of using this paint transfer gear pump?

A: Users benefit from its high operational efficiency, leak-proof design, low noise levels, and ability to handle paints with solids up to 2% by volume. Its corrosion-resistant construction and compliance with ISO 9001:2015 ensure reliable performance and regulatory peace of mind.Q: How does the pumps self-priming and suction capability improve performance?

A: Self-priming allows the pump to begin transferring paint without needing external priming systems, while the 5-meter maximum suction enhances installation flexibility and ensures consistent flow even when paint is drawn from lower elevations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Gear Pumps Category

Fuel Injection Gear Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Frequency : 50/60 Hz

Power : Other, 0.52 HP

Seals Type : Mechanical Seal

LDO Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50 Hz

Power : Other, 0.5 HP to 5 HP

Seals Type : Mechanical Seal

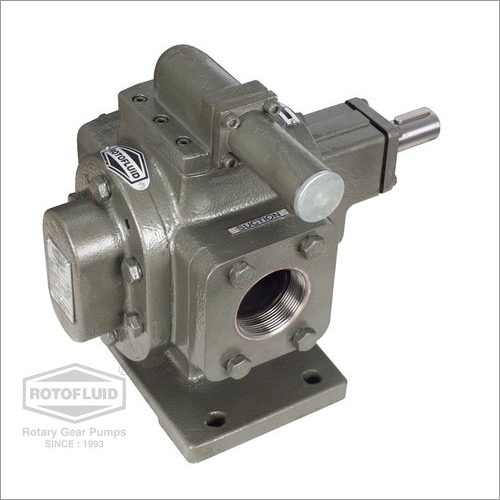

SS Gear Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Frequency : 50/60 Hz

Power : Other, 0.5 to 10 HP

Seals Type : Mechanical seal / Gland packing

Fluid Coupling Rotary Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50/60 Hz

Power : Other, 0.53 HP

Seals Type : Mechanical Seal

|

FLUID TECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry