|

LDO Boiler Firing Gear Pump

Price 2500.00 INR/ Piece

LDO Boiler Firing Gear Pump Specification

- Voltage

- 220V / 380V / 415V, 50Hz / 60Hz (As Per Requirement)

- Flow Rate

- 20 LPM to 500 LPM

- Head Size

- Upto 100 Meters

- Discharge Pressure

- Max 10 bar

- Working Temperature

- Upto 150C

- Frequency

- 50Hz / 60Hz

- Inlet/Outlet

- 3/4 BSP (Standard), Custom Sizes Available

- Max Suction

- 5 Meters

- Caliber

- Customizable

- Noise Level

- <70 dB

- Speed

- 1440 RPM / 2880 RPM

- Features

- High Efficiency, Low Noise, Leak Proof, Compact Design

- Fuel Tank Capacity

- As per system design

- Control System

- Manual / Automated

- Mounting Type

- Foot Mounted / Base Plate Mounted

- Theory

- Rotary Positive Displacement

- Material

- Cast Iron / Stainless Steel / Alloy Steel

- Structure

- Single / Double Stage External Gear Pump

- Power

- 0.5 HP - 10 HP

- Standard

- IS 11501 / Equivalent

- Fuel Type

- Light Diesel Oil (LDO), Furnace Oil, HSD

- Pressure

- Upto 10 bar

- Usage

- LDO Boiler Firing, Oil Transfer, Industrial Applications

- Application

- Boiler Firing, Fuel Feeding

- Suction Type

- Vertical / Horizontal

- Seals Type

- Mechanical Seal / Gland Packing

- Priming

- Self Priming

- Pump Type

- Gear Pump

- Capacity

- 20-500 LPH

- Coupling Type

- Flexible Coupling

- Direction of ROTATION

- Clockwise / Anti-Clockwise

- Painting/Coating

- Anti-Corrosive, Epoxy Coated

- Relief Valve

- Integrated / Optional

- Viscosity Range

- Up to 5000 CST

- Service Life

- Long operational life with minimal maintenance

- Shaft Material

- EN8 / SS304 / SS316

- Flange Standard

- ANSI / DIN Standard

LDO Boiler Firing Gear Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-5 Days

About LDO Boiler Firing Gear Pump

Unmatched Versatility in Industrial Oil Transfer

Engineered for reliability, the LDO Boiler Firing Gear Pump suits a vast range of industrial environments. It accommodates various fuels, viscosities, and operating speeds, supporting both clockwise and anti-clockwise rotation. Its flexible coupling and base-plate mounting options allow seamless integration into existing systems, while robust construction ensures consistent performance.

Durable Materials & Superior Coating

Constructed from EN8, stainless steel (SS304/SS316), or alloy steel, every pump resists corrosion and wear. An anti-corrosive, epoxy coating provides an extra layer of protection, supporting a long operational life even under demanding conditions. This durability, complemented by minimal maintenance, maximizes operational uptime.

Effortless Priming and Leakage Control

Designed with self-priming capability and advanced sealingchoose between mechanical seal or gland packingthese pumps offer quick starts and extended leak-free performance. Integrated or optional relief valves further protect your system, ensuring safe and smooth fuel transfer every time.

FAQs of LDO Boiler Firing Gear Pump:

Q: How does the LDO Boiler Firing Gear Pump improve fuel transfer efficiency?

A: This pump utilizes rotary positive displacement principles, enabling consistent and precise flow rates from 20 LPM to 500 LPM, even at high viscosities up to 5000 CST. Its self-priming design, minimal noise (<70 dB), and high mechanical efficiency ensure optimized, reliable fuel transfer operations.Q: What types of oils and fuels can this gear pump handle?

A: The pump is suitable for Light Diesel Oil (LDO), Furnace Oil, and High-Speed Diesel (HSD), with a viscosity range up to 5000 CST. Its robust construction and advanced sealing options make it ideal for a spectrum of industrial and boiler applications.Q: Where can the LDO Gear Pump be installed, and how is it mounted?

A: The pump is versatile in installation, supporting foot-mounted or base plate mounting. Its flexible coupling and compact design allow for easy integration into a variety of boiler rooms, industrial plants, or oil transfer stations.Q: What makes the LDO Boiler Firing Gear Pump durable and long-lasting?

A: Durability is ensured through the use of EN8, SS304, or SS316 steel, as well as alloy steel options. Its anti-corrosive epoxy coating protects against harsh fuels and environments, and integrated relief valves prevent pressure-related damage.Q: When is the integrated relief valve necessary, and is it optional?

A: The integrated relief valve provides overload protection by managing excess pressure within the system. It is highly recommended for all installations, though available as optional, for enhanced safety and smooth operation.Q: How does the pump maintain low maintenance and minimal downtime?

A: The mechanical design, durable materials, and advanced sealing significantly reduce maintenance needs. High-quality coatings and efficient operation minimize wear, while the self-priming design and reliable relief valves further limit downtime.Q: What are the control and customization options for this gear pump?

A: Customers can opt for manual or automated control systems. The pumps inlet/outlet sizes, shaft materials, coating options, flange standards, and mounting types are customizable to fit specific operational needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Pumps Category

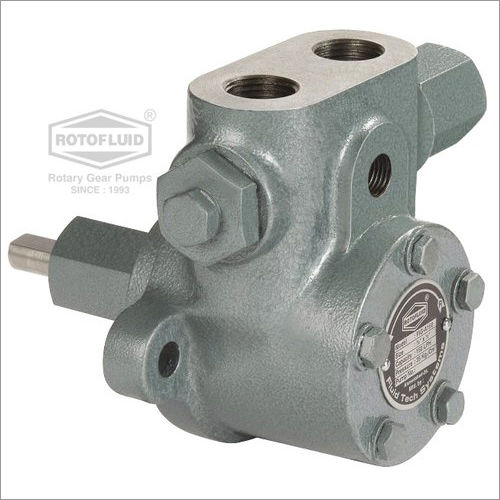

Cast Iron Gear Pumps

Minimum Order Quantity : 01 Piece

Power : Other, 0.5 HP to 15 HP

Material : Cast Iron Body, Alloy Steel Gears

Standard : IS Standard/ISOCompliant

Inlet/Outlet : 1/2 to 4 BSP (Threaded) or Flanged

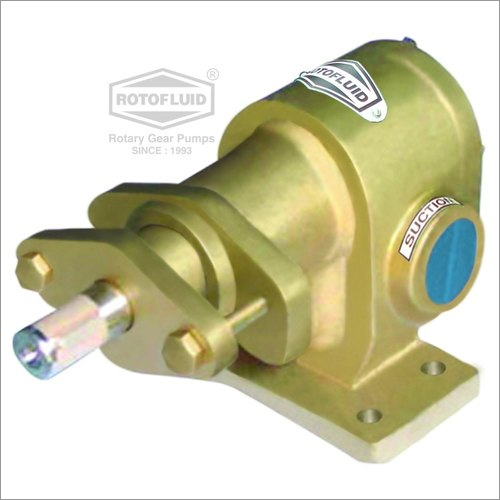

Gunmetal Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power : Other, 0.5 HP to 25 HP

Material : Gunmetal / Bronze

Standard : ISO 9001:2015

Inlet/Outlet : 1 to 3 BSP (optional flange end)

Chemical Twin Rotary Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power : Other, 0.5 HP to 20 HP

Material : Cast Iron / Stainless Steel (SS304 / SS316)

Standard : ISO 9001

Inlet/Outlet : 1 to 6 BSP (Flanged/Threaded)

Filling Machine Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power : Other, 0.55kW

Material : Stainless Steel

Standard : ISO 9001

Inlet/Outlet : 25mm / 25mm

|

FLUID TECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry