Most Popular Products

|

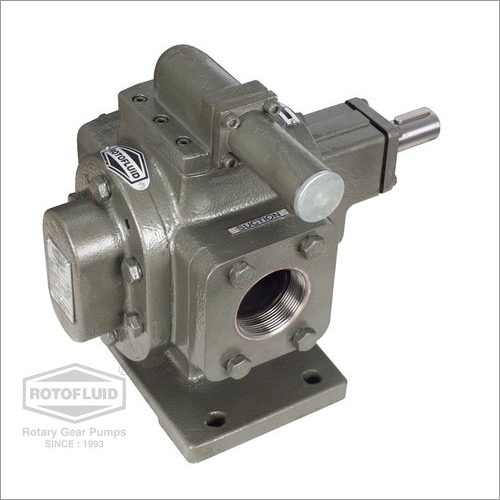

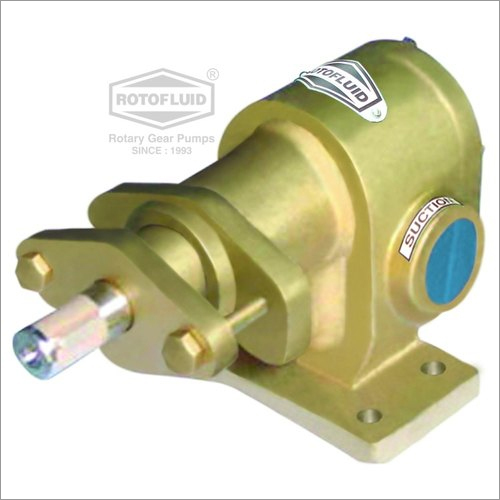

Textile Machine Gear Pump

Price 2500.00 INR/ Piece

MOQ : 1 Piece

Textile Machine Gear Pump Specification

- Max Suction

- Up to 5 meters

- Speed

- 1440 RPM

- Caliber

- 3/8 inch

- Theory

- Rotary Gear Pump

- Control System

- Manual Operated

- Inlet/Outlet

- 3/8 inch BSP

- Discharge Pressure

- 6 bar

- Head Size

- Up to 60 meters

- Voltage

- 230 V

- Features

- High Efficiency, Compact Design, Long Life

- Mounting Type

- Base Mounted

- Working Temperature

- Up to 180C

- Frequency

- 50 Hz

- Flow Rate

- 10 LPM

- Noise Level

- Low

- Material

- Stainless Steel

- Structure

- Single Stage

- Power

- 0.5 HP

- Standard

- ISI Standard

- Fuel Type

- Electric

- Pressure

- Up to 6 bar

- Usage

- Textile Machine Lubrication

- Application

- Textile Machinery, Printing, Dyeing

- Suction Type

- Positive Displacement

- Seals Type

- Mechanical Seal

- Priming

- Self Priming

- Pump Type

- Gear Pump

- Capacity

- 10 LPM

- Connection Type

- Threaded

- Lubrication

- Self-lubricated

- Installation Position

- Horizontal

- Impeller Type

- External Gear

- Direction of Rotation

- Clockwise

- Service Life

- Up to 5 years

- Corrosion Resistance

- Yes

- Surface Finish

- Polished or Matt

Textile Machine Gear Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-5 Days

About Textile Machine Gear Pump

A textile machine gear pump is a specialized pump used in the textile industry for the precise and controlled delivery of fluids in various textile processes. These pumps play a crucial role in applications such as dyeing, printing, coating, and finishing, where accurate and uniform distribution of liquids is essential for high-quality textile production. The gear pump mechanism provides reliable and consistent flow rates, ensuring optimal process performance.

FAQ:

Q: What are the main features of a textile machine gear pump?

A: Textile machine gear pumps are designed to provide precise flow control and consistent delivery of fluids. They often have a compact and robust construction, allowing integration into textile machinery. These pumps may feature adjustable flow rates, precise metering capabilities, and materials compatible with the fluids used in textile processes.

Q: What are the advantages of using a textile machine gear pump?

A: Using a textile machine gear pump offers several advantages. These pumps provide accurate and controlled fluid delivery, resulting in uniform dyeing, printing, or coating across the textile material. They offer reliable performance with consistent flow rates, ensuring consistent quality in textile production. Textile machine gear pumps also allow for easy adjustment and fine-tuning of flow parameters to meet specific process requirements.

Q: Can textile machine gear pumps handle a wide range of fluids and viscosities?

A: Yes, textile machine gear pumps are designed to handle a variety of fluids commonly used in textile processes, including dyes, pigments, thickeners, and other chemical solutions. They can handle fluids with different viscosities, from thin to more viscous liquids. The pump selection should consider the specific fluid properties and viscosity requirements of the textile application.

Q: Are textile machine gear pumps suitable for high-pressure applications?

A: Textile machine gear pumps are generally designed for medium to low-pressure applications commonly found in textile processes. However, specialized models with enhanced pressure capabilities may be available for specific requirements. It is important to select a pump that can handle the pressure range required for your textile application.

Q: How do I select the right textile machine gear pump for my application?

A: Selecting the right textile machine gear pump depends on factors such as the required flow rate, pressure, viscosity of the fluid, temperature, and the specific textile process involved. Consulting with pump specialists or manufacturers experienced in textile applications can help determine the most suitable pump for your specific needs.

High-Efficiency Gear Pump for Textile Machinery

Designed to meet stringent ISI standards, this single-stage rotary gear pump provides consistent lubrication for textile machines, as well as printing and dyeing units. The compact structure, positive displacement suction, and 1440 RPM speed guarantee dependability and quick installation. Its base-mounted, manual control system allows easy operation and maintenance, making it a preferred choice for industry professionals.

Durable, Corrosion-Resistant Construction

Manufactured from premium stainless steel with a polished or matte finish, the pump offers superior corrosion resistance even in demanding industrial environments. The mechanical seal and self-lubricated design contribute to a long service life of up to five years, ensuring reduced downtime for users and consistent, safe performance throughout its operational cycle.

Versatile Application and User-Friendly Features

This gear pump supports voltages of 230 V and functions efficiently at working temperatures up to 180C. Featuring threaded 3/8 inch BSP inlet/outlet connections and a flow rate of 10 LPM, it serves a broad spectrum of applications. Its low noise operation and compact, base-mounted configuration make integration seamless across textile production facilities.

FAQs of Textile Machine Gear Pump:

Q: How is the Textile Machine Gear Pump installed and positioned for efficient operation?

A: The pump is designed for horizontal installation and base mounting, ensuring stable and reliable performance. Proper positioning allows optimal lubrication in textile machinery, printing, and dyeing setups.Q: What materials and surface finishes are available for this gear pump?

A: This pump is constructed from high-grade stainless steel, available with either polished or matt surface finishes. These features enhance corrosion resistance and longevity in demanding environments.Q: When should this pump be used in textile machinery applications?

A: It is ideal for continuous lubrication in textile machines, especially in settings requiring high efficiency and low maintenance, such as printing and dyeing lines. The self-priming and positive displacement features support uninterrupted operations.Q: Where can this gear pump be sourced or supplied?

A: The pump is distributed, exported, supplied, and manufactured in India, making it accessible through various channels including distributors, wholesalers, and direct manufacturer sales.Q: What is the process for connecting and operating the gear pump?

A: Installation involves threaded 3/8 inch BSP inlet/outlet connections, manual control operation, and powering by a 230 V electric source. The pump is self-lubricated and uses a mechanical seal for leak-free functioning.Q: How does the pump benefit textile machinery with its design and features?

A: With high efficiency, compact design, low noise, and a long service life of up to five years, the pump minimizes maintenance, improves system reliability, and maintains optimal lubrication across all textile machine components.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Gear Pumps Category

Motorized Gear Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Seals Type : Mechanical seal

Power : Other, 0.5 HP to 3 HP

Material : Cast Iron / Stainless Steel (optional)

Fluid Coupling Rotary Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Seals Type : Mechanical Seal

Power : Other, 0.53 HP

Material : Cast Iron

Lube Oil Transfer Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Seals Type : Mechanical Seal / Gland Packing

Power : Other, 0.5 HP to 15 HP

Material : Cast Iron / SS 304 / SS 316

Diesel Transfer Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Seals Type : Mechanical Seal

Power : Other, 0.75 kW

Material : Cast Iron

|

FLUID TECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry