|

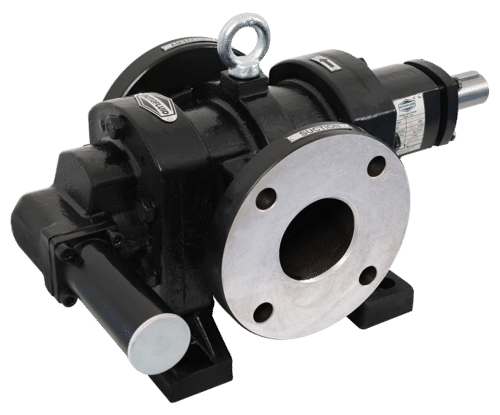

Internal SS Gear Pump

Internal SS Gear Pump Specification

- Caliber

- Up to 50 mm (2 inch)

- Voltage

- 220-415 V Volt (v)

- Flow Rate

- 10 to 1500 LPH

- Max Suction

- 5 Mtrs.

- Discharge Pressure

- Up to 10 kg/cm

- Mounting Type

- Baseplate/foot mounted

- Inlet/Outlet

- BSP/NPT threaded or flange connection

- Head Size

- Up to 100 meters

- Frequency

- 50/60 Hz Hertz (HZ)

- Noise Level

- Low db

- Theory

- Rotary Pump

- Working Temperature

- Up to 120C Celsius (oC)

- Features

- Corrosion resistant, robust construction, compact design

- Control System

- Manual / Electric

- Speed

- Up to 1440 RPM RPM

- Material

- Stainless Steel (SS-304/316)

- Structure

- Horizontal

- Power

- 0.5 to 10 HP

- Standard

- ISO 9001 Certified

- Fuel Type

- Electric motor driven

- Pressure

- Up to 10 bar

- Usage

- Other

- Application

- Other

- Suction Type

- Positive displacement

- Seals Type

- Mechanical seal / Gland packing

- Priming

- Self-priming

- Pump Type

- External gear pump

- Capacity

- 10 to 1500 LPH Ltr/hr

- Viscosity Range

- Up to 1,00,000 CST

- Surface Finish

- Polished

- Leakage

- Minimal (Sealed construction)

- Shaft Material

- Stainless Steel

- Portability

- Stationary

- Direction of Rotation

- Clockwise/Counterclockwise

- Cooling Method

- Air cooled

- Maintenance

- Low maintenance

Internal SS Gear Pump Trade Information

- Minimum Order Quantity

- 01 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-5 Days

- Main Domestic Market

- All India

About Internal SS Gear Pump

Fluid Tech Systems offer ROTOFLUID brand gear pump Model FTSS (SS Rotary Gear Pump) which is self priming, foot mounting type positive displacement rotary gear pump. Model FTSS having all Stainless Steel (SS-316) in three piece construction with investment cast. Due to three piece construction, it can be easily cleanable and maintainable that is why it is highly used in all kind of food industries. These pumps have SS-316 Gear and shaft that are nitrated to give long life and trouble free performance. The shaft is supported on self lubricating type Ptfe coated Bushes and the sealing is done with Ptfe based GFO pack sealant which gives zero leakage. The right angle mounting brackets facilitates foot mounting of the pump on base plate with Electric Motor of appropriate ratings. These pumps have sturdy design and construction for long trouble free service.

The suction and delivery connection are available in 1/4" to 2 1/2" size. These pumps can be operated up to pressure of 10 kg/cm² with 8.33 LPM to 300 LPM flow capacity and has suction lift of 1m to 5m at rated speed of 1440 RPM. These pumps are designed up to maximum Viscosity to 1,00,000 SSU and maximum temperature up to 200oC.

Product details

| Material | SS |

| Model | FTSS |

| Brand | Rotofluid |

Engineered for High Performance

This gear pump excels at efficiently transferring liquids with viscosities up to 100,000 CST, making it suitable for a wide array of demanding industrial applications. The construction utilizes stainless steel for excellent corrosion resistance and longevity under continuous operation. Air-cooled and equipped with heavy-duty bearings, it delivers reliable performance even in rigorous settings requiring sustained usage.

Versatility and Reliability

The pumps ability to handle a wide flow rate range, up to 1500 LPH, as well as withstand working temperatures up to 120C, ensures versatility across several industries. Its polished, compact design and stationary installation contribute to ease of integration into diverse process settings while minimizing maintenance requirements.

Advanced Sealing and Minimal Leakage

Equipped with mechanical seal and gland packing options, this SS gear pump ensures minimal leakage for safe and clean operation. The sealed construction, combined with positive displacement and robust engineering, allows for effective handling of sensitive chemicals and hygiene-critical fluids, such as those in the food or pharmaceutical sectors.

FAQs of SS Gear Pump:

Q: How does the SS Gear Pump accommodate various viscosities and what materials can it handle?

A: The SS Gear Pump is engineered to transfer fluids with viscosities up to 100,000 CST, thanks to its positive displacement mechanism and strong stainless steel construction. It can handle a broad spectrum of liquids, including oils, chemicals, food products, cosmetics, pharmaceuticals, and dyes.Q: What are the primary benefits of using a stainless steel gear pump in process industries?

A: Stainless steel gear pumps offer excellent corrosion resistance, making them ideal for transferring aggressive or high-purity fluids. They ensure minimal leakage, low maintenance, and are suitable for hygienic, chemical, and industrial applications, aligning with ISO 9001 standards.Q: When is it preferable to use a gear pump with mechanical seal or gland packing?

A: Mechanical seals are recommended when handling hazardous, volatile, or valuable fluids to prevent leakage, while gland packing is suitable for less demanding applications. The pump provides both sealing options to suit different operational safety and process requirements.Q: Where can the SS Gear Pump be installed, and how is it typically mounted?

A: This gear pump is designed for stationary installation, typically baseplate or foot mounted, integrating seamlessly into various industrial setups. It is suitable for indoor chemical plants, pharmaceutical workshops, and process lines in food or cosmetics industries.Q: What process advantages does the self-priming feature offer during pump operation?

A: Self-priming capability allows the pump to automatically evacuate air from the suction line without manual assistance, ensuring fast startup and continuous operation. This reduces downtime and operational intervention, especially important in batch processing.Q: How is minimal leakage achieved in this gear pump, and why is this important?

A: Minimal leakage is accomplished via sealed construction with advanced sealing options, which preserves the integrity of sensitive or hazardous fluids, enhances workplace safety, and reduces fluid loss, crucial in regulated industries like pharmaceuticals and food.Q: What are the control options and operating conditions for the SS Gear Pump?

A: The pump can be operated manually or with electric controls, functions between 220-415V, and handles temperatures up to 120C, pressures up to 10 bar, and capacities ranging from 10 to 1500 LPH, supporting both clockwise and counterclockwise rotations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Pumps Category

Bitumen Pumps

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : High Viscosity Handling, Low Maintenance, Sturdy Construction

Control System : Manual / Automatic

Priming : Self Priming

Application : Other, Industrial / Road Construction

Petroleum Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : High efficiency, reliable sealing, easy maintenance

Control System : Manual/Automatic

Priming : Self Priming

Application : Other, Filling stations, Oil transfer, Industrial lubrication

Paint Gear Pump

Minimum Order Quantity : 01 Piece

Features : Corrosion Resistant, Leakproof, Easy Maintenance

Control System : Manual or Automatic

Priming : Self Priming

Application : Other, Industrial Painting Systems, Paint Circulation

Three Phase Helical Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Robust design, High efficiency, Leak proof operation, Compact structure

Control System : Manual/Electrical panel

Priming : Self priming

Application : Other, Transfer of oil, viscous fluids, solvents

|

FLUID TECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry