|

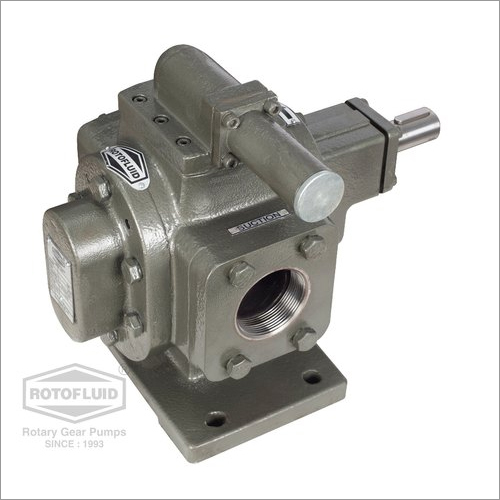

Internal Jacketed Gear Pump

Internal Jacketed Gear Pump Specification

- Voltage

- 415 V Volt (v)

- Max Suction

- Up to 5 meters

- Theory

- Rotary Positive Displacement

- Noise Level

- Below 70 dB db

- Working Temperature

- -10C to 200C Celsius (oC)

- Speed

- Up to 1440 RPM RPM

- Mounting Type

- Base Plate Mounted

- Head Size

- Up to 100 meters

- Discharge Pressure

- Up to 10 bar

- Caliber

- Standard / Custom

- Flow Rate

- Up to 500 LPM

- Inlet/Outlet

- 1 to 6 (Flanged/Threaded)

- Frequency

- 50 Hz / 60 Hz Hertz (HZ)

- Control System

- Manual / Automatic

- Features

- Heating jackets for handling high viscosity or temperature-sensitive liquids

- Material

- Cast Iron / Stainless Steel / Alloy Steel

- Structure

- Single Stage, Jacketed body and cover

- Power

- 0.5 HP to 50 HP

- Standard

- ISO 9001

- Fuel Type

- Electric

- Pressure

- Up to 10 bar

- Usage

- Other

- Application

- Other

- Suction Type

- Positive Suction

- Seals Type

- Mechanical Seal / Gland Packing

- Priming

- Self Priming

- Pump Type

- Jacketed Gear Pump

- Capacity

- Up to 30,000 LPH Ltr/hr

- Heating Media

- Hot water, steam, or oil

- Rotation Direction

- Clockwise (Standard) / Anti-clockwise (Optional)

- Body Coating

- Anti-corrosion coated

- Viscosity Range

- Up to 100,000 cSt

- Impeller Type

- Gear-type

- Surface Finish

- Painted / Coated / Polished

- Connection Type

- Threaded or Flanged

- Maintenance

- Low maintenance requirement

Internal Jacketed Gear Pump Trade Information

- Minimum Order Quantity

- 01 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-5 Days

- Main Domestic Market

- All India

About Internal Jacketed Gear Pump

These pumps are having flange at the end of suction and delivery which are available in 1/2" to 6" size. These pumps can be operated up to pressure of 10 kg/cm2 with 8.30 LPM to 2083.00 LPM flow capacity. These pumps are suitable for liquid up to viscosity of 1, 00,000 SSU and maximum temperature up to 200oC

Pump Selection

Model FTRN/FTRB : The self lubricated needle roller bearing type Model FTRN used for clean viscous liquid having sufficient lubricating property such as clean lube oil, Gear oil, Animal oil, Fish oil, Hydraulic oil, Honey, Vegetable oil, SAE lubricating oil for continues duty, However for Intermittent duty Bush Bearing type pump Model FTRB used.

Model FTRX : This Model independent lubricated needle roller bearing type pump is suitable for handling of Crude oil, Dirty lube oil, HSD, Kerosene, LDO, Paints, Varnish, Wood Pulp, Liquid which have poor lubricant value.

Model FTRBJ : This Model should be selected for liquid which tends to solidify at room temperature such as Bitumen, Furnace oil, Asphalt, Tar, Starch, Molasses, Naptha, RFO, Silicate, Wax, Soap solution. Because This model have jacketing construction facilitate the heating the pump by steam or thermic fluid.

Product details

|

Size |

1/2 x 1/2 |

|

Max Flow Rate |

2080 LPM |

|

Brand |

Roto Fluid |

|

Model |

FTRBJ |

|

Material |

MS |

Versatile Compatibility for High-Viscosity Media

This jacketed gear pump is ideal for industries dealing with highly viscous or temperature-sensitive products. Thanks to its heating capability, it effectively handles substances such as bitumen, syrup, molasses, chocolate, and specialty oils, ensuring optimal flow and process continuity. Its ability to maintain product temperature during transfer protects material quality and process efficiency.

Flexible Installation and Easy Maintenance

Available with both threaded and flanged connections, the pump supports straightforward installation across diverse operational environments. Its self-priming nature, positive suction design, and low maintenance requirements minimize downtime, enabling reliable operation. The ball and roller bearing options, paired with durable body coatings, enhance service life and resist corrosion.

Precision Performance and Operational Safety

Featuring a single-stage, rotary positive displacement mechanism, this pump delivers flow rates up to 30,000 LPH and heads up to 100 meters. With a low noise level under 70 dB and clear options for manual or automatic control systems, operators benefit from a safe, user-friendly, and energy-efficient solution, suitable for continuous industrial transfer applications.

FAQs of Jacketed Gear Pump:

Q: How does the heating jacket enhance the operation of the Jacketed Gear Pump?

A: The heating jacket allows for circulation of hot water, steam, or oil around the pump body, ensuring that high-viscosity or temperature-sensitive liquids remain fluid during transfer. This prevents clogging, promotes smooth flow, and protects product integrity throughout the pumping process.Q: What types of liquids can this gear pump handle effectively?

A: This pump is specifically designed for viscous materials up to 100,000 cSt, including bitumen, molasses, chocolate, syrup, soap, and a variety of oils. The jacketed design and anti-corrosion coating make it suitable for challenging industrial fluids that require precise temperature control.Q: When is it beneficial to use a jacketed gear pump instead of a standard gear pump?

A: A jacketed gear pump is ideal in scenarios where the liquid being transferred is highly viscous or temperature-sensitive. The jacketed feature is essential when maintaining or elevating temperature is necessary to reduce viscosity, such as with bitumen, chocolate, or heavy oils, ensuring continuous and efficient flow.Q: Where can this jacketed gear pump be installed within industrial operations?

A: The pump can be base plate mounted and is suitable for installations in various sectors, including chemical processing plants, refineries, food manufacturing units, and facilities handling specialty fluids. Flexible connection options (threaded or flanged) further enhance its adaptability to existing systems.Q: What is the process for maintaining this gear pump, and how frequently is servicing required?

A: Thanks to its robust design with ball or roller bearings and high-quality seals, the pump requires minimal maintenance. Regular checks of the bearing lubrication, seal integrity, and heating jacket connections are recommended, but overall servicing intervals are less frequent compared to conventional pumps.Q: How does the positive displacement mechanism benefit the user?

A: The rotary positive displacement mechanism ensures a consistent, pulsation-free flow, regardless of changes in pressure or viscosity. This makes the pump reliable for delicate or precise transfer tasks, allowing for accurate dosing and reducing the risk of product loss or process interruptions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Pumps Category

Cast Iron Gear Pumps

Minimum Order Quantity : 01 Piece

Theory : Other, Rotary Pump (External Gear type)

Suction Type : Positive Suction

Pressure : Other, Up to 10 Bar

Power : Other, 0.5 HP to 15 HP

Reversible Rotary Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Theory : Other, Rotary Gear Pump

Suction Type : Positive Suction

Pressure : Other, Up to 5 kg/cm

Power : Other, 0.5 HP to 10 HP

High Pressure Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Theory : Other, Rotary Gear Pump

Suction Type : Positive Displacement

Pressure : Other, Up to 25 Bar

Power : Other, 0.5 HP to 30 HP

SS Foam Fire Fighting Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Theory : Other, Rotary Gear Pump

Suction Type : Positive Displacement

Pressure : Other, 3.5 bar

Power : Other, 2 HP

|

FLUID TECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry