|

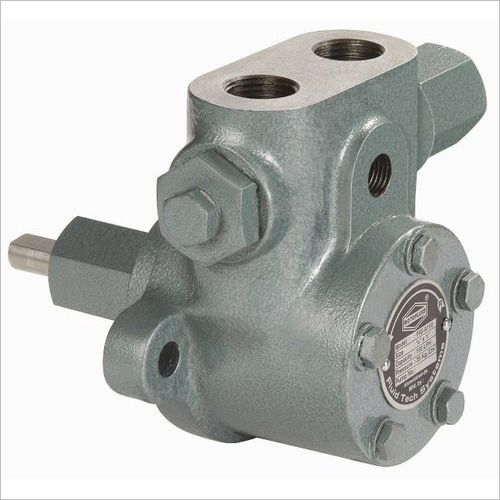

Viscous Liquid Pump

Viscous Liquid Pump Specification

- Head Size

- Up to 40 m

- Frequency

- 50 Hz / 60 Hz

- Theory

- Rotary Pump

- Max Suction

- 7 m

- Control System

- Manual / Automatic

- Mounting Type

- Base Mounted

- Caliber

- As per Model

- Flow Rate

- Up to 60 m/hr

- Noise Level

- < 70 dB

- Features

- Corrosion Resistant, Heavy Duty, High Efficiency

- Speed

- 720-2880 rpm

- Inlet/Outlet

- 1 to 4 (25 mm to 100 mm)

- Voltage

- 380 V

- Working Temperature

- -10C to 120C

- Fuel Tank Capacity

- N/A (Electric Pump)

- Discharge Pressure

- Up to 6 Bar

- Material

- Cast Iron / Stainless Steel

- Structure

- Single / Double Stage

- Power

- 0.5 HP to 15 HP

- Standard

- ISO 5199 / DIN Standard

- Fuel Type

- Electric Driven

- Pressure

- Up to 6 Bar

- Usage

- Industrial Applications

- Application

- Viscous Liquid Transfer

- Suction Type

- Positive Displacement

- Seals Type

- Mechanical Seal / Gland Packing

- Priming

- Self-Priming

- Pump Type

- Gear / Screw / Lobe Pump

- Capacity

- Up to 60 m/hr

- Shaft Material

- SS 304 / SS 316

- Bearing Type

- Anti-Friction Bearings

- Temperature Control

- Optional Heating Jacket

- Direction of Rotation

- Reversible

- Surface Finish

- Painted / Polished

- Color

- Blue / As Per Requirement

- Motor Protection

- IP55 / IP65

- Viscosity Supported

- Up to 200,000 cSt

- Service

- Continuous Duty

- Media Type

- Suitable for Oil, Syrup, Resin, Glue, Creams, Slurry

Viscous Liquid Pump Trade Information

- Minimum Order Quantity

- 01 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-5 Days

- Main Domestic Market

- All India

About Viscous Liquid Pump

Fluid Tech Systems offer ROTOFLUID brand internal gear pump Model FIG (Fuel injection Internal Gear Pump, LDO Gear Pump, Burner Firing Gear Pump, Boiler Firing Gear Pump, FIG Pump, HSD Gear Pump, Diesel Filling Gear Pump) which is high precision and fuel pressuring type positive displacement internal gear pump which prepared by graded cast iron. These nitrated gear , shafted rotor give better performance with closed tolerance to give long life. Model FIG is flange mounted. These pumps are self priming type produces maximum, vacuum determined by the cavity between the gear teeth. These pumps modified profile teeth cutting to give accurate capacity with in the pressure range. These pumps are capable to run liquid up to 500 CST viscosity and up to temperature 200oC. The sealing is done with mechanical seal to ensure zero leakage.

The suction and delivery connections are available in 3/8",1/2",3/4"and 1" size. Model FIG pump come in a capacity Range of 60 LPH to 6000 LPH with operating pressure up to 35 kg/cm2, yet for continuous duty maximum recommended pressure is 30kg/cm2. These pumps can also be used at 2800 RPM. The capacity will have approx double of normal duty condition. These pump can be run both clock and anti clock direction as per requirement.

Product details

| Voltage | 220V |

| Brand | Rotofluid |

| Motor Horsepower | 3 HP |

| Motor Speed | 1000 RPM |

| Material | MS |

| Model | FTRN/FTRB |

| Frequency | 50Hz |

Exceptional Viscosity Handling Capability

Designed to manage liquids with exceptionally high viscositiesup to 200,000 cStthis pump ensures reliable transfer of oils, syrups, resins, glues, and even slurries. The positive displacement mechanism, combined with self-priming, facilitates consistent and efficient fluid movement in demanding industrial settings.

Versatile Construction and Operation

Available in both Cast Iron and Stainless Steel (SS 304/316), this pump adapts to various corrosive environments. It features a reversible rotational direction, optional heating jacket, and anti-friction bearings for long-term, continuous operation. Multiple seal and mounting options further enhance installation flexibility.

Advanced Safety and Control Features

Motor protection is ensured with IP55 or IP65 ratings, and users can select between manual or automatic control systems. The painted or polished finish adds durability, while compliance with ISO 5199 and DIN standards guarantees operational reliability and user safety in a wide range of industrial processes.

FAQs of Viscous Liquid Pump:

Q: How does the pump handle extremely viscous liquids during operation?

A: The pump employs a positive displacement mechanism with self-priming capability, allowing it to efficiently transfer liquids with viscosities up to 200,000 cSt without loss in performance. Its robust construction and anti-friction bearings ensure smooth, continuous duty even under high viscosity conditions.Q: What types of industries and media are suitable for this viscous liquid pump?

A: This pump is ideal for industrial applications involving the transfer of oils, syrup, resin, glue, creams, and slurries. It is commonly used in food processing, chemical manufacturing, pharmaceutical production, and other sectors requiring efficient handling of thick or challenging fluids.Q: When is it recommended to use the optional heating jacket?

A: The optional heating jacket is advisable when handling fluids that are prone to solidification or require specific temperature maintenance within the -10C to 120C range. It keeps the medium at optimal viscosity for trouble-free pumping, especially in colder environments or with temperature-sensitive substances.Q: Where can the pump be installed and what are the mounting options?

A: This pump is designed for base-mounted installation, making it suitable for integration into existing processing lines or as a standalone transfer unit in industrial plants. Its compact and sturdy build allows flexibility in various workspace layouts.Q: What is the process for controlling and operating the pump?

A: Control can be managed manually or through an automatic system, depending on operational needs. The pump supports both IP55 and IP65 motor protection, offering secure and safe working conditions. Operation is straightforward, with guidance available from the manufacturer or supplier as needed.Q: What benefits does the corrosion-resistant construction provide?

A: The use of Cast Iron and Stainless Steel (SS 304/316) ensures the pump resists corrosion, extending its service life and efficiency when handling harsh chemicals or abrasive media. This durability minimizes maintenance costs and unscheduled downtimes, benefiting continuous industrial operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Pumps Category

Liquid Filling Machine Gear Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Seals Type : Mechanical Seal

Pump Type : Other, Gear Pump

Pressure : Other, 01.2 bar

Structure : Other, Integral Compact Modular Base

Fuel Injection Internal Gear Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Seals Type : Mechanical Seal

Pump Type : Other, Internal Gear

Pressure : Other, Up to 8 bar

Structure : Other, Single Stage

Jacketed Gear Pump

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Seals Type : Mechanical Seal / Gland Packing

Pump Type : Other, Rotary Gear Type

Pressure : Other, Up to 10 kg/cm

Structure : Other, Jacketed Gear Pump Design

FIG Pumps

Price Range 2500.00 - 3200.00 INR / Piece

Minimum Order Quantity : 01 Piece

Seals Type : Mechanical Seal

Pump Type : Other, FIG Self Priming Pumps

Pressure : Other, Standard

Structure : Other, Single Stage

|

FLUID TECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry