|

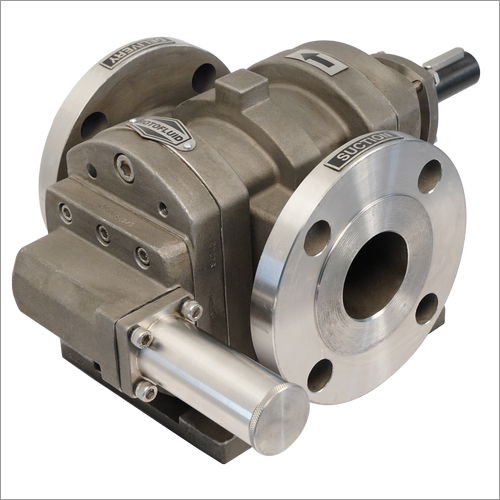

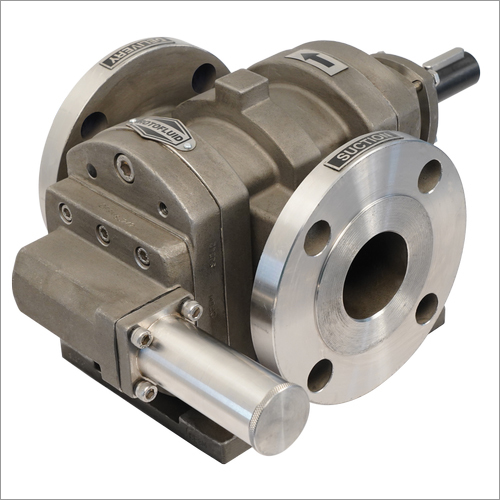

SS Rotary Twin Gear Pumps

Price 2500.00 INR/ Piece

SS Rotary Twin Gear Pumps Specification

- Features

- Corrosion-resistant, Leak-proof, Compact Design

- Head Size

- Up to 100 meters

- Caliber

- Multiple available sizes (specify as per application)

- Speed

- Up to 1440 RPM

- Discharge Pressure

- Up to 10 kg/cm

- Mounting Type

- Foot / Base mounted

- Frequency

- 50 Hz / 60 Hz

- Max Suction

- Up to 5 meters

- Flow Rate

- 15 to 500 LPM

- Theory

- Positive Displacement Rotary Twin Gear

- Working Temperature

- -10C to 200C

- Control System

- Manual / Automatic

- Inlet/Outlet

- 1 to 4 BSP (customizable)

- Voltage

- 415 V AC (Three Phase) / 230 V AC (Single Phase)

- Noise Level

- Low noise operation

- Material

- Stainless Steel SS-304 / SS-316

- Structure

- Rotary Twin Gear Design

- Power

- 0.5 HP to 20 HP

- Standard

- IS 1248/1983

- Fuel Type

- Electric powered

- Pressure

- Up to 10 kg/cm

- Usage

- Chemical, Pharma, Food Processing, Petroleum

- Application

- Transfer, Circulation, Loading, Unloading of various fluids

- Suction Type

- Positive Suction

- Seals Type

- Mechanical Seal / Gland Pack

- Priming

- Self-priming

- Pump Type

- Rotary Twin Gear Pump

- Capacity

- Upto 30 m/hr

- Lubrication Type

- Self-lubricating gears

- Max Solid Size

- Recommended for clean fluids; consult for sizes

- End Connection

- Flanged / Threaded BSP

- Bearings

- Heavy-duty Ball / Sleeve Bearings

- Direction of Rotation

- Clockwise (standard); counterclockwise available

- Maintenance

- Easy-to-service modular design

- Body Finish

- Mirror / Matt Finish

- Viscosity Range

- Up to 1,00,000 cst

- Shaft Material

- Stainless Steel

SS Rotary Twin Gear Pumps Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-5 Days

About SS Rotary Twin Gear Pumps

Robust Stainless Steel Construction

The pumps are crafted from high-grade stainless steel, available in SS-304 or SS-316, ensuring superior durability and resistance against corrosion. This robust construction not only extends the pumps lifespan but also keeps maintenance requirements low, making it suitable for demanding industrial environments.

Wide Viscosity and Temperature Range

Designed to accommodate fluids with viscosities up to 100,000 cst and operate within a temperature window of -10C to 200C, these rotary twin gear pumps provide flexible solutions for a variety of processes, including the transfer of chemicals, oils, and food-based products safely and efficiently.

Easy Maintenance, Modular Design

Simple modular assembly allows for quick servicing and easy part replacement, reducing downtime and operational costs. The self-lubricating gears and heavy-duty ball/sleeve bearings further optimize reliability and ease of maintenance, ensuring smooth daily operation.

Versatile Applications and Customization

With a compact structure, different mounting types, customizable inlet/outlet connections, and control system options, these pumps suit multiple industrial uses such as fluid transfer, circulation, and loading/unloading operations. Their efficient priming and positive suction capabilities support installation in diverse operating conditions.

FAQs of SS Rotary Twin Gear Pumps:

Q: How does the SS Rotary Twin Gear Pump handle high viscosity fluids?

A: The pumps positive displacement design allows it to efficiently move fluids with viscosities up to 100,000 cst, making it ideal for heavy oils, syrups, and other dense liquids common in chemical, food, and pharma industries.Q: What maintenance processes are involved with these pumps?

A: Maintenance is straightforward due to the pumps modular design and easy-to-service components. Routine checks typically include inspecting the bearings and seals; aside from this, the self-lubricating gears minimize the need for frequent lubrication.Q: Where can these pumps be installed, and are mounting options available?

A: They are suitable for installation in industrial settings like chemical plants, food production facilities, and oil refineries. Mounting can be done on the foot or base, providing flexibility depending on the available space and operational requirements.Q: What are the benefits of choosing a stainless steel rotary twin gear pump for my process?

A: Selecting a stainless steel pump ensures excellent corrosion resistance, longevity, and suitability for handling aggressive and hygiene-sensitive fluids. Its leak-proof and low-noise operation enhances workplace safety and comfort.Q: What process is used to change the direction of rotation in these pumps?

A: The standard configuration is clockwise rotation, but it can be customized to counterclockwise during assembly or by contacting your supplier for specific adaptations.Q: In what applications or fluids are these pumps recommended?

A: These pumps are recommended for transferring, circulating, loading, and unloading clean fluids without large solids. They are widely used in chemical, pharmaceutical, food processing, and petroleum industries for precise fluid management.Q: How does the self-priming feature enhance pump operation?

A: Self-priming capability allows the pump to quickly and efficiently begin pumping without manual priming, reducing start-up time and supporting smoother operations, especially in transfer and loading/unloading tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Pumps Category

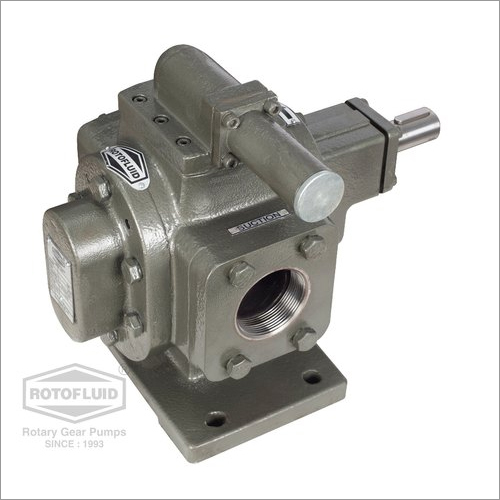

Corrosive Chemical Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Pressure : Other, Max 10 Bar

Material : PP / SS304 / SS316 / PVDF

Flow Rate : 0.5 m3/h to 30 m3/h

Suction Type : Positive Suction

High Pressure Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Pressure : Other, Up to 25 Bar

Material : Cast Iron / Alloy Steel / Stainless Steel

Flow Rate : Up to 500 LPM (liter per minute)

Suction Type : Positive Displacement

HSD Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Pressure : Other, Up to 10 bar

Material : Cast Iron / Stainless Steel

Flow Rate : 5 LPM to 500 LPM

Suction Type : Positive Suction

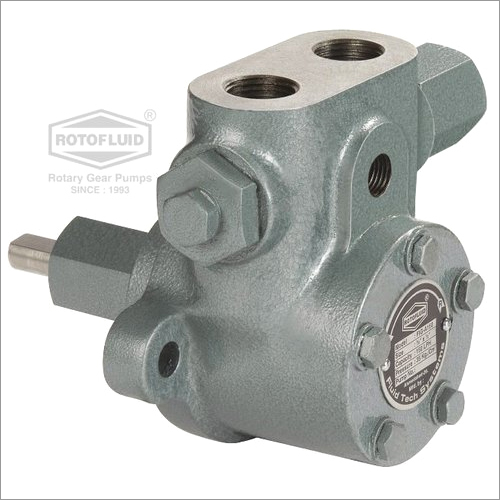

Lubrication Oil Gear Pumps

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Pressure : Other, Up to 10 bar

Material : Cast Iron / Stainless Steel

Flow Rate : 10 LPM to 500 LPM

Suction Type : Positive Displacement

|

FLUID TECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry